Laser Marking Additives are revolutionizing plastic laser marking, enabling high-contrast, durable, and precise engravings across industries like automotive, electronics, and packaging. This guide explores what laser marking additives are, how they work, their benefits, and key considerations for choosing the right solution for your application.

What Are Plastic Laser Marking Additives?

Laser Marking Additives, also known as laser colorants, powders, or masterbatches, are specialized compounds added to plastics to enhance their laser sensitivity. Plastics naturally resist laser energy, resulting in faint or unclear marks. Plastic laser marking additives solve this by absorbing laser energy, converting it into heat, and enabling clear, high-contrast engravings without compromising the plastic’s color or performance.

These additives are ideal for industries requiring precise markings, such as barcodes, logos, or identification marks on products like cables, automotive parts, and medical devices. By incorporating laser marking additives, manufacturers achieve faster, sharper, and more durable engravings on materials like PP, PE, PC, and nylon.

How Do Laser Marking Additives Work?

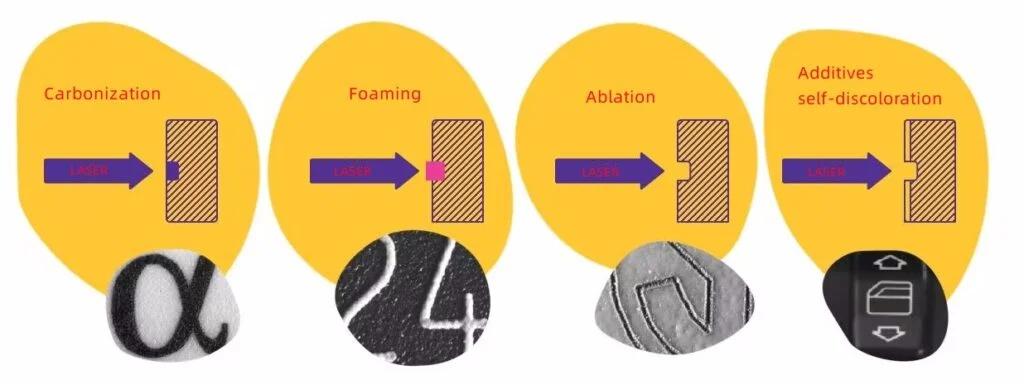

Laser marking additives enhance plastic laser marking by absorbing laser energy and triggering specific reactions in the plastic substrate. The laser beam, emitted as high-energy pulses, interacts with the additive to produce effects like:

- Carbonization: Heat from the laser chars the plastic, creating dark marks on light-colored substrates (e.g., black marks on white plastic).

- Foaming: The additive generates bubbles within the plastic, producing light-colored marks on dark substrates (e.g., white marks on black plastic).

- Ablation: High-energy lasers vaporize the plastic surface, creating textured, concave marks, often used in laser direct structuring (LDS).

- Self-Discoloration: Additives undergo chemical changes under laser exposure, darkening the mark for high-contrast results.

These mechanisms ensure plastic laser marking delivers precise, permanent, and visually striking results tailored to the substrate and desired effect.

Benefits of Using Laser Marking Additives

Plastic laser marking with additives offers significant advantages over traditional marking methods like printing or spraying:

- Eco-Friendly: No solvents or consumables are needed, reducing environmental impact.

- Flexible Design: Easily edit patterns, fonts, or barcodes via laser software for customized results.

- High Precision: Achieve micro-marks and high-resolution graphics with unmatched accuracy.

- Durable Markings: Marks resist fading, wear, and environmental factors like UV exposure.

- Cost-Effective: Non-contact process minimizes tool wear and eliminates the need for pre-treatments.

- Sustainable: Facilitates recycling by avoiding pollutants and ensuring clean marking processes.

These benefits make laser marking additives a top choice for industries seeking reliable, high-quality marking solutions.

Types of Plastic Laser Marking Techniques

Laser marking additives enable various marking effects based on the plastic substrate and desired outcome:

- Dark Marks on Light Plastics: High laser heat causes carbonization, producing gray or black marks. Ideal for white or light-colored substrates.

- Light Marks on Dark Plastics: Foaming creates bubbles that reflect light, resulting in white or light marks on dark substrates like black PP or PE.

- Color Marking: Additives or pigments react to laser energy, creating vibrant color changes on specific plastics for decorative or functional purposes.

Each technique leverages laser marking additives to achieve high-contrast, durable results tailored to your application.

Choosing Between Laser Marking Powder and Masterbatch

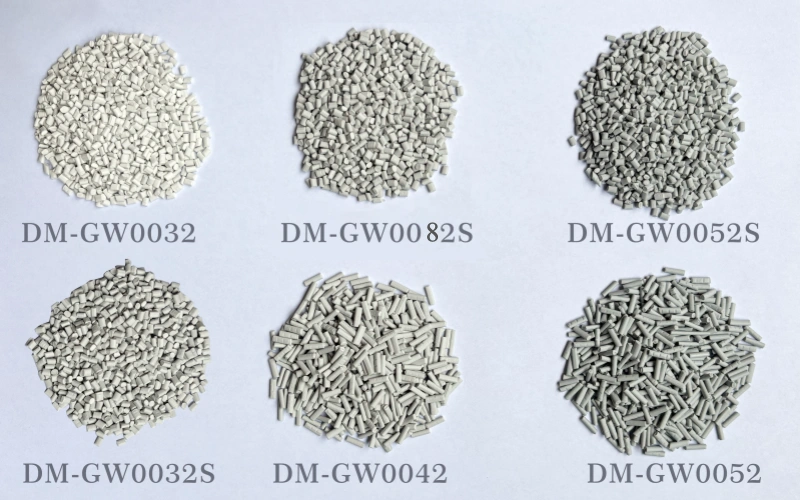

Laser marking additives come in two forms: powder and masterbatch. Here’s how to choose:

- Laser Marking Powder:

- Addition Rate: 0.3%–0.5% (3–5 grams per kg of plastic).

- Pros: Cost-effective due to lower usage; ideal for high-precision applications.

- Cons: Heavier powder may settle during direct injection, requiring granulation for uniform dispersion.

- Laser Marking Masterbatch:

- Addition Rate: 2%–5% (20–50 grams per kg of plastic).

- Pros: Granular form ensures easy dispersion during injection molding; suitable for automated processes.

- Cons: Higher addition rate increases costs.

Recommendation: Use masterbatch for direct injection molding and powder for granulation processes to balance cost and performance.

Compatible Plastics for Laser Marking Additives

Laser marking additives are versatile, supporting a wide range of plastics and alloys, including:

- General Plastics: PP, PE (LDPE, HDPE), PVC, PS, TPE, TPV, TPR, PET.

- Engineering Plastics: PC, PA, PBT, POM, PEI, nylon, epoxy resin.

- Plastic Alloys: PC+ABS.

- Thermally Conductive Plastics: PPS, PA6/PA66, LCP, PEEK (used in LED lighting, automotive, and refrigeration).

- Thermoplastic Elastomers: TPE, TPU, TPR, TPV (used in wires, shoe materials, and pipes).

These additives ensure clear, durable marks even on challenging substrates, enhancing traceability and aesthetics.

Factors Affecting Plastic Laser Marking Quality

Several factors influence the effectiveness of plastic laser marking with additives:

- Additive Amount:

- Powder: 0.3%–0.5%.

- Masterbatch: 1%–3%.

- Increase amounts for plastics with flame retardants or fibers.

- Raw Material Quality:

- Virgin, natural-colored plastics yield the best results.

- Avoid black pigments like carbon black, which reduce marking clarity.

- Laser Machine Type:

- UV Lasers: Stable but limited to specific plastics; higher maintenance costs.

- Infrared Lasers (Fiber, UV, Nd: YAG): Versatile, fast, and cost-effective for most plastics.

- Laser Parameters:

- Adjust power, frequency, and scan speed for optimal heat and contrast.

- Low power/low frequency for dark marks on light plastics; high power/high frequency for light marks on dark plastics.

- Additives and Fillers:

- Flame retardants or excessive carbon black (>1.5%) can reduce marking clarity.

- Glass fibers or beads have minimal impact.

- Material Preparation:

- Dry plastics before adding additives to avoid degradation.

- Avoid baking additives with raw materials unless specified for high-melting-point plastics.

By optimizing these factors, you can achieve superior plastic laser marking results.

How to Use Laser Marking Additives Effectively

Follow these steps to maximize the effectiveness of laser marking additives:

- Dry Raw Materials: Ensure plastics are moisture-free before adding additives to prevent degradation.

- Mix Thoroughly: Blend additives (powder or masterbatch) evenly with raw materials. Use masterbatch for direct injection or granulate powder for uniform dispersion.

- Injection Molding: Process the plastic as usual, then mark the finished product with a laser machine.

- Adjust Laser Parameters: Fine-tune power, frequency, and speed to achieve the desired contrast and clarity.

- Test and Optimize: Conduct trials to balance additive amounts and laser settings for cost-effective, high-quality results.

Storage Tips:

- Store additives in a dry, ventilated area to prevent moisture absorption.

- Use within 24 months and keep sealed when not in use.

Applications of Laser Marking Additives

Laser marking additives are widely used across industries for functional and decorative purposes:

- Automotive: Marking buttons, dashboards, and connectors (e.g., PBT, nylon).

- Electronics: Barcodes and logos on ABS keypads and circuit components.

- Packaging: Traceability marks on PET, HDPE, and LDPE containers.

- Medical: Sterilization-safe markings on hospital equipment and animal ear tags.

- Consumer Goods: Durable engravings on appliance shells, cosmetic packaging, and light switches.

- Thermally Conductive Materials: Clear markings on PPS, PA6/PA66, and PEEK for LED and automotive applications.

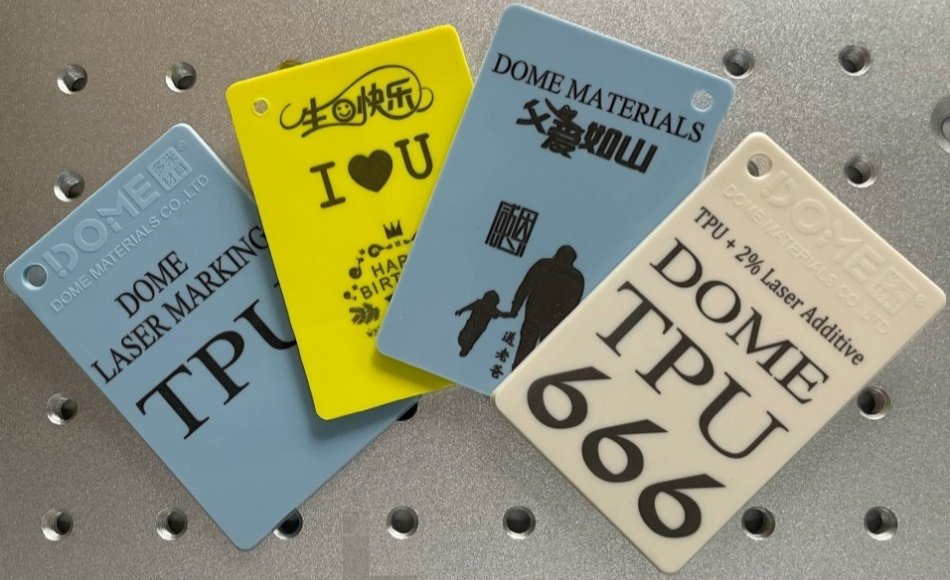

- Elastomers: High-contrast marks on TPE, TPU, and TPV for wires and shoe materials.

These applications highlight the versatility and reliability of plastic laser marking solutions.

Why Choose DOME for Laser Marking Solutions?

DOME, with over a decade of expertise, offers advanced laser marking additives tailored to your needs. Our additives deliver:

- High-Contrast Markings: Achieve clear, vibrant marks on colored or transparent plastics.

- Compatibility: Suitable for most polymers and laser systems.

- Regulatory Compliance: Safe, stable, and environmentally friendly formulations.

- Expert Support: Guidance on additive selection and laser parameter optimization.

Contact DOME at DOMEMATERIALS.COM to explore our solutions and elevate your plastic laser marking projects.

Conclusion

Laser marking additives are essential for achieving precise, durable, and high-contrast markings on plastics. By enhancing laser sensitivity, these additives enable industries to produce clear engravings on materials like PP, PE, PC, and TPU, improving traceability, aesthetics, and functionality. Key considerations include selecting the right additive form (powder or masterbatch), optimizing laser parameters, and choosing compatible plastics.

For expert guidance and high-quality laser marking additives, partner with DOME. Visit DOMEMATERIALS.COM to learn more and start enhancing your plastic laser marking process today.