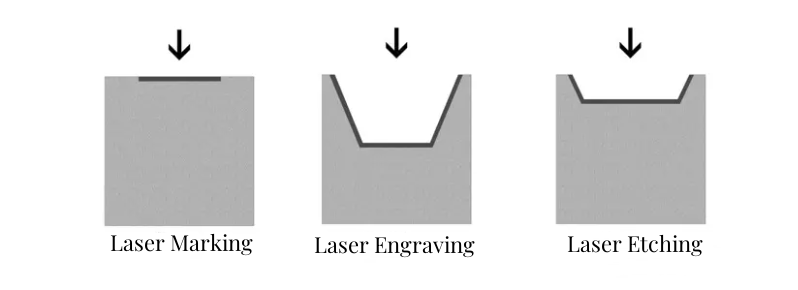

Laser marking, laser engraving, and laser etching are all methods used to create marks or designs on various materials using a laser beam. While they may seem similar, there are key differences between these processes:

1. Laser marking:

In laser marking, a high-intensity laser beam interacts with the surface of a material, causing a chemical or physical reaction to create a permanent mark. This process usually results in high-contrast marks with minimal material removal. Laser marking is commonly used for adding text, serial numbers, barcodes, or logos to products for identification or branding purposes.

2. Laser Engraving:

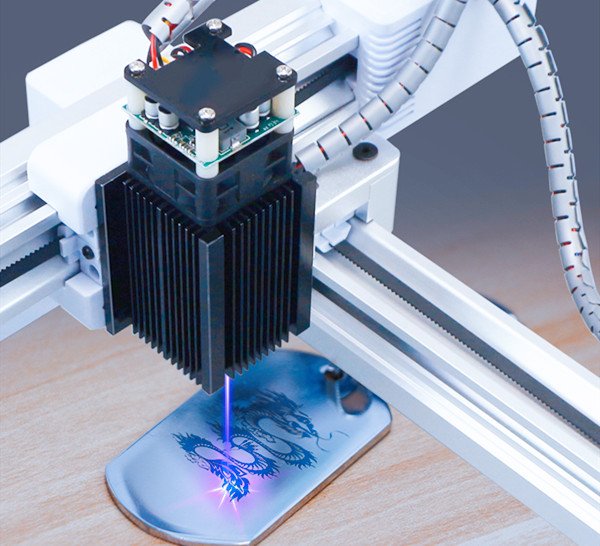

Laser engraving involves removing layers of material from the surface using a laser beam. The laser vaporizes or melts the material, leaving behind a cavity that forms the desired mark or design. Laser engraving can create deep, crisp, and precise markings on a variety of materials, including wood, acrylic, metal, glass, and more. It is often used for decorative purposes, personalization, or creating detailed designs.

3. Laser Etching:

Laser etching is similar to laser engraving but typically refers to a shallower, more subtle mark. Instead of vaporizing or melting the material, the laser partially removes the surface layer, resulting in a frosted or matte appearance. This technique is commonly used on glass, stone, plastics, or coated metals to create intricate and delicate designs without compromising the structural integrity of the material.

In summary, laser marking is a method for creating permanent marks on surfaces, laser engraving involves removing material to create deep and precise marks, and laser etching refers to a lighter mark achieved by partially removing the surface layer. The choice between these techniques depends on the desired result, material type, and specific application.

What is the process of Laser Marking, Etching, and Engraving?

Laser marking, etching, and engraving are common processes used to create permanent markings on various surfaces. While these processes are similar in nature, they differ in the way they interact with the material being marked.

1. The Process of Laser Marking:

Laser marking is a non-contact process that uses a high-powered laser beam to create marks on the surface of a material. The laser beam interacts with the surface, causing a chemical or physical reaction that creates a permanent mark. Laser marking is commonly used to add branding, identification numbers, logos, or other information to a wide range of materials, including metals, plastics, ceramics, glass, and even organic materials like wood or leather. The marking process typically involves high precision and produces high-quality, highly visible marks with minimal damage to the material.

2. The Process of Laser Etching:

Laser etching is a process similar to laser marking but involves removing material from the surface to create a mark. The laser beam vaporizes or burns away the top layer of the material, creating a shallow, permanent mark. Laser etching is commonly used to create detailed and intricate designs, such as artwork, serial numbers, or text, on materials like metal, plastic, glass, or stone. It offers high precision and can achieve very fine details, making it suitable for various applications including product customization and personalization.

3. The Process of Laser Engraving:

Laser engraving is a deeper and more substantial process than laser marking or etching. It involves removing a significant amount of material from the surface to create a visible and tactile mark. The laser beam vaporizes or melts the material, creating a cavity or recessed area. Laser engraving is commonly used to create text, graphics, or images that are more prominent and permanent. It is often employed on materials like metals, wood, acrylic, glass, and stone. The process allows for deep and detailed engravings that can be used for artistic or functional purposes, such as signage, plaques, or personalized items.

Overall, laser marking, etching, and engraving are versatile and precise processes used to create permanent markings on various materials. They offer benefits like high precision, durability, and the ability to mark complex designs, making them widely used in industries such as manufacturing, electronics, automotive, aerospace, and personalized product manufacturing.

Who Uses Laser Marking for Plastics?

Various industries and businesses use laser marking for plastics. Some examples include:

1. Automotive industry:

Laser marking is commonly used to mark identification codes, serial numbers, logos, and other information on plastic components and parts used in automobiles.

2. Electronics industry:

Laser marking is utilized to mark labels, barcodes, and serial numbers on plastic electronic devices, circuit boards, connectors, and cables.

3. Medical devices:

Laser marking is essential for marking identification codes, lot numbers, and safety information on plastic medical devices and tools, such as syringes, implants, surgical instruments, and prosthetics.

4. Packaging industry:

Laser marking is used to mark packaging information, expiration dates, batch codes, and labels on plastic packaging materials, containers, bottles, and pouches.

5. Consumer goods industry:

Laser marking is employed for branding, decorative designs, logos, and product information on various plastic consumer goods like toys, cosmetics, appliances, and household items.

6. Aerospace industry:

Laser marking is crucial for marking identification codes, part numbers, and other information on plastic components used in aircraft, satellites, and space equipment.

7. Electrical and telecommunications industry:

Laser marking is utilized for marking information, labels, and codes on plastic components used in electrical equipment, power switches, connectors, and telecommunication devices.

These are just a few examples, and laser marking for plastics is also used in many other industries where durable and high-quality marking on plastic materials is required.

Why Does Your Business Need Laser Marking?

There are several reasons why a business may need laser marking. Some of the key reasons include:

1. Identification and branding:

Laser marking provides a permanent and high-quality way to identify products with logos, serial numbers, barcodes, or other custom markings. This helps in branding and establishing product authenticity.

2. Traceability and quality control:

Laser marking enables businesses to track products throughout the supply chain by creating unique identification marks. This helps in reducing counterfeiting, improving inventory management, and ensuring product quality.

3. Compliance and regulations:

Certain industries, such as medical devices or aerospace, have strict regulations regarding product markings. Laser marking ensures compliance with these regulations and facilitates product traceability.

4. Durability and longevity:

Laser markings are highly resistant to wear and tear, making them ideal for products that undergo frequent handling or are exposed to harsh environments. The permanence of laser markings also adds to product value and reliability.

5. Flexibility and versatility:

Laser marking can be performed on a wide range of materials, including metals, plastics, glass, ceramics, and more. This versatility allows businesses to mark their products regardless of the material used.

6. Efficient and cost-effective:

Laser marking is a fast and efficient process, allowing businesses to mark multiple products quickly. This reduces production time and costs compared to traditional marking methods.

7. Customization and personalization:

Laser marking offers the ability to create intricate and detailed designs, enabling businesses to personalize products for individual customers or add unique features to attract a specific target market.

Overall, laser marking provides businesses with a reliable and versatile solution for product identification, traceability, compliance, and customization, ultimately enhancing brand value and customer satisfaction.

Why do you need a laser marking additive for your polymer?

There are several reasons why laser additives are needed for polymer laser marking:

1. Enhanced Contrast: Laser additives help improve the contrast between the marked area and the surrounding polymer material. This is crucial for ensuring the legibility and visibility of the markings.

2. Increased Durability: Laser additives can enhance the durability of the marked polymer surface. They help in preventing fading or degradation of the markings over time, ensuring long-lasting and reliable visibility.

3. Improved Ablation Efficiency: Laser additives can optimize the ablation efficiency of the laser marking process. They enhance the absorption of laser energy by the polymer material, leading to more precise and efficient marking.

4. Broadened Material Compatibility: Some polymers may not be easily laser-markable due to their inherent properties. Laser additives can help overcome this limitation by modifying the polymer’s characteristics, making it compatible with laser marking processes.

5. Customization Options: Laser additives offer the flexibility to customize the marking process. They can be tailored to specific requirements such as color, texture, or special effects, allowing for unique and personalized markings on polymer surfaces.

Overall, laser additives play a crucial role in optimizing the laser marking process for polymers by improving contrast, durability, efficiency, material compatibility, and customization options.

Why choose DOME laser additives?

Looking for the perfect laser marking additive for plastics? Look no further than DOME Materials, the leading laser additives manufacturer in China. With our competitive wholesale prices and fast delivery (RTS), we are your go-to solution provider.

At DOME Materials, we understand the importance of finding the best solution for your laser marking needs. That’s why we offer a wide range of high-quality laser additives specifically designed for plastics. Our additives are carefully formulated to deliver exceptional results, ensuring precise and durable laser markings on plastics.

As the leading manufacturer in China, we take pride in our advanced technology and state-of-the-art facilities. Our team of experts is committed to developing innovative laser marking additives that meet the highest industry standards. With our cutting-edge products, you can achieve superior laser markings that enhance the appearance and functionality of your plastic products.

What sets us apart from the competition is our commitment to customer satisfaction. We offer competitive wholesale prices, allowing you to get the best value for your investment. Additionally, our fast delivery (RTS) ensures that you receive your laser additives promptly, minimizing any production delays.

Choose DOME Materials as your trusted partner for laser marking additives. With our expertise and dedication, we guarantee exceptional products at the most competitive prices. Contact us today to find the best solution for your laser marking needs.

Contact Us Today to Learn More

With our laser marking additives, you can achieve the clear, high-quality marks your company needs.

To learn more about our laser additives, and what they will accomplish for you, be sure to contact us and we’ll be happy to answer any questions you may have.