Manufacturer in China

LASER MARKING ADDITIVE FOR PLASTIC

DOME Materials is a professional Laser Marking Additive manufacturer and wholesale supplier in China.

Check Out Our Selection of Laser Marking Masterbatches for Your Polymers.

- Free Samples

- Fast Delivery

- Customizable

- Competitive Price

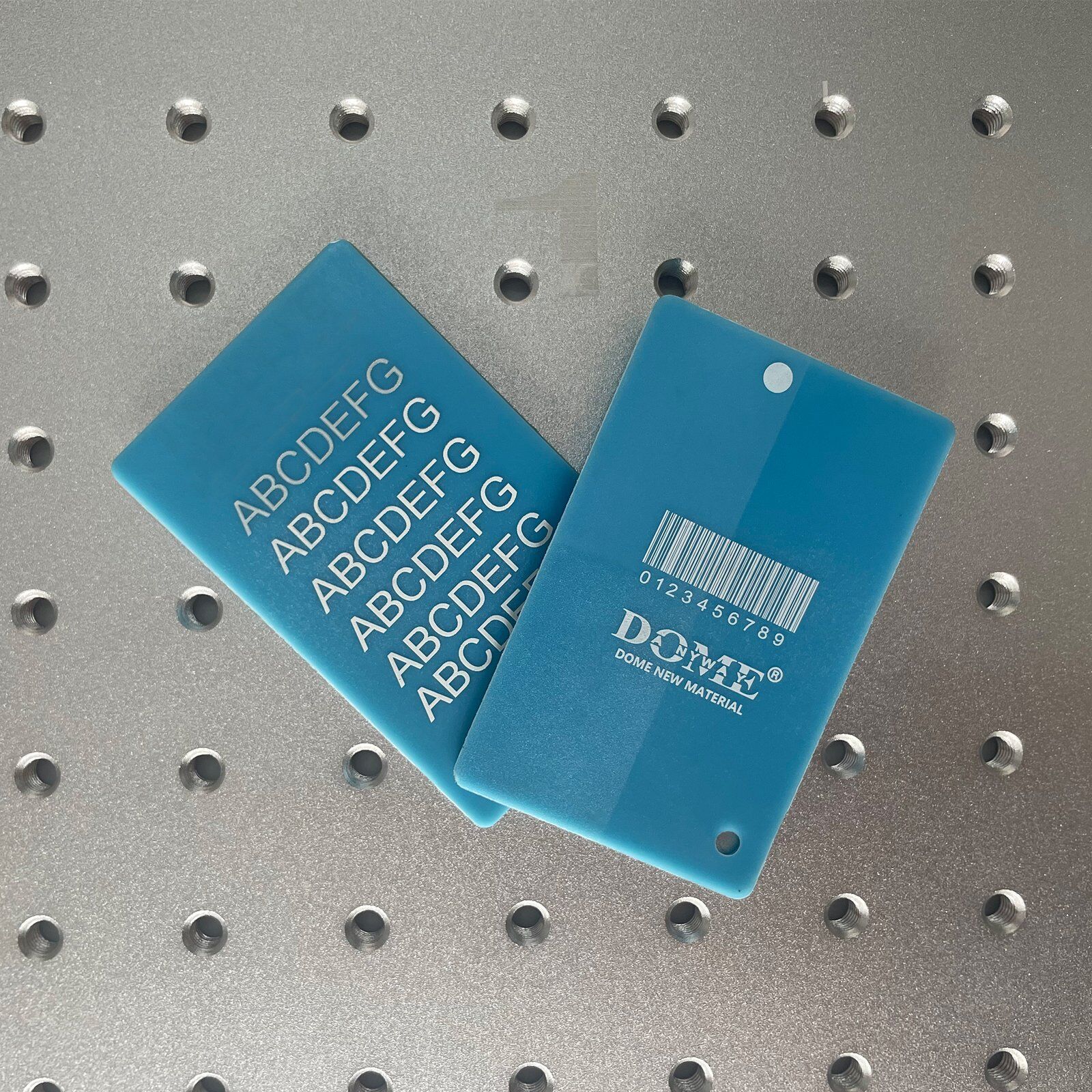

Product Model: DM- GG0033

Laser Marking on Plastics: Achieving Superior Contrast with Additives

Laser marking is a widely used technique for creating permanent, precise markings on plastic materials using controlled laser beams. To achieve high-contrast markings, especially when marking white on colorful plastic surfaces, laser marking additives are often essential.

This method is highly popular for everyday applications, including marking plastic packaging, cables, security seal tags, and electronic components. By enhancing the material with specialized additives, manufacturers can ensure sharp, durable, and visually striking results on plastic products.

Take Your Business To The Next Level

DOME™ Materials Plastic Laser Marking Additives have revolutionized industries with their ability to create clear, permanent, and high-contrast laser white marks on plastic materials. These advanced laser marking masterbatches are indispensable in various applications, including TPU livestock ear tags and security seals made from PP, POM, ABS, and PBT, ensuring enhanced security and reducing the risk of counterfeiting.

For the electronics industry, DOME additives deliver precise, durable marks that improve product traceability and authenticity verification. In the food packaging sector, these plastic laser marking solutions ensure safety, compliance, and quality, meeting rigorous industry standards.

The growing adoption of DOME Laser Marking Additives underscores their significant role in boosting security, traceability, and safety across diverse industries.

Application - White Mark on Colored Polymer

Laser marking on plastics is an advanced, precise, and efficient technique that delivers clear, permanent, and durable markings on various plastic surfaces. This technology is especially effective in marking white contrasts on colored plastics, making it a preferred solution across the plastics industry.

DOME™ laser marking additives, also referred to as laser-sensitive additives or laser-activated additives, are widely utilized for diverse applications. These include plastic PP security seals, lead seals, safety seals, and seals for water, electricity, and gas. Additionally, DOME additives are essential for marking colored electronic products such as earphones and smartwatches, along with colored home appliances, cables, medical equipment, skin care product packaging, and daily essentials.

The versatility and reliability of DOME™ laser marking solutions make them a leading choice for ensuring high-contrast, lasting markings in industries demanding traceability, safety, and quality.

Laser White Mark on PP Security Seal Tags

Laser White Mark on ABS Lead Seals

Laser White Mark on ABS Injected Medical Parts

White Laser Marking on POM Agricultural Plastic Nozzles Orchard and Speciality Crops

Laser White Mark on ABS POM PBT PA66 Lead Seals

Laser White Mark on PA6/PA66 Water Meter

DOME™ Laser Marking Additives

Top picks Laser Additives In Stock:

| Product Name | Model No. | Compatibility | Dosage | Laser Type |

| Laser Marking Masterbatch – Black Mark on Color Plastic | DM-GW0032 | Universal | 1-5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) |

| DM-GW0042 | PP | 1-5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-GW0052 | PC | 1-5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-GW0062 | Universal | 1-4% | UV Laser(355nm), Green Laser(532nm) | |

| Laser Marking Masterbatch – White Mark on Black Plastic | DM-GB0031 | Universal | 0.5-0.6% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) |

| DM-GB0041 | PC | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-GB0051 | ABS | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-GB0061 | Universal | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| Laser Marking Masterbatch – Black Mark on Transparent Plastic | DM-GB0030 | PP | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) |

| DM-GB0040 | PC | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| Laser Marking Masterbatch – White Mark on Color Plastic | DM-GG0033 | Universal | 1-3% | UV Laser(355nm), Green Laser(532nm) |

| Laser Marking Powder – Black Mark on Color Plastic | DM-PW0036 | Universal | 0.2-0.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) |

| DM-PW0046 | ABS | 0.2-0.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-PW0056HE | PBT | 0.1-0.3% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| Laser Marking Powder – White Mark on Black Plastic | DM-PB0037 | Universal | 0.2-0.5% | UV Laser(355nm), Green Laser(532nm) |

Laser Marking Masterbatch - White Laser Mark on Colored Products

Wholesale at Competitive Prices

Don’t miss out and take advantage of our factory prices. Check out our catalog and see only the best deals for you and your Polymer laser marking needs. On top of our competitive prices, enjoy huge discounts for bulk orders as well.

In our well-maintained raw material warehouse spanning 1000 square meters, we maintain a consistent and reliable inventory of raw materials. This enables us to minimize the expenses associated with raw material procurement. As the foremost manufacturer of laser marking additives in China, we offer a comprehensive one-stop service. Typically, orders weighing up to 5 tons are swiftly delivered within 1-3 working days, effectively reducing procurement costs and enhancing operational efficiency for our valued customers.

Features and Benefits of Laser Marking for Plastic

- Non-contact processing, durability;

- High precision, fast, high legibility, reliability;

- Forming a top-quality micro mark;

- Environment-friendly;

- Easy to use, strong security features;

- Strong traceability of products;

- High-speed automatic processing can be achieved ;

- The overall production cost of individual parts is far less than that of printing traditional inks.

Black Mark on Color Polymer

White Mark on Black Polymer

White Mark on Color Polymer

Black Mark on Transparent Polymer

White Mark on black Products – Laser Marking Powder

Black Mark on Color Products – Laser Marking Powder

Customized Laser Marking Additives & Custom Modified Compounds

Our laser marking aids are suitable for a variety of plastic materials, such as PE / PP / PC / TPU / ABS / PC+ABS / PBT / HIPS, etc.

We can also provide custom-modified masterbatches upon request. You have the choice between purely laser additive masterbatches or combination masterbatches, consisting of carrier polymer, additives, and the color of your choice. such as modified ABS materials for the ABS keyboard (70% ABS Resin + 30% PMMA +4% Laser Marking Masterbatch), custom modified TPU materials for livestock ear tags (TPU Resin + Laser Marking Additive + Pigment), and modified materials for cables, etc.

We do not require a minimum order quantity for the laser marking additives, so you can buy according to the actual needs of your project, no need to make an additional inventory.

Package and Storage

- Caton Size: 500*380*160mm | 420*380*160mm

- Weight: 25Kgs/carton | 20Kgs/carton

- Laser additive is packaged in a plastic box or a carton lined with a PE bag;

- Laser additive is non-dangerous goods;

- Please store in dry and ventilated conditions;

- Waterproof and moisture-proof;

- Avoid sun exposure;

- Please seal the unused portion of the Laser additive;

- Please use it up within 24 months.

- DELIVERY: 1-3 working days under 5000Kgs, 5-7 working days for Biger Order

Frequently Asked Questions

This section contains a few FAQs that our customers ask. If your question is not here, contact us today, and we will answer directly.

What is the ideal percentage of laser marking additive to achieve the best results?

Adding excessive amounts of laser marking additive does not enhance marking accuracy. For optimal results, we recommend using 1%-2%, with a maximum limit of 5%. To improve the marking effect, consider adjusting the laser machine’s parameters instead.

Can I use a fiber laser machine to laser mark white marks on my colored plastic products?

No, fiber laser machines are not suitable for laser marking white on colored products. You need a UV laser marking machine with a wavelength of 355nm or a green laser marking machine with a wavelength of 532nm.

How to adjust laser marking parameters?

To optimize laser marking, it is essential to fine-tune various parameters in the laser machine. These crucial parameters consist of speed, power, frequency, line spacing, and filling type. However, it is important to note that different laser machine brands and models may require different parameter adjustments even when marking the same plastic product. Consequently, a continuous process of experimentation and parameter adjustment is necessary to attain the most optimal and effective marking outcome.

Will adding laser marking additives to colored or white plastics affect the original color of my product?

Basically, it will not affect the color matching, because the amount of laser marking additives added is relatively small, only 0.3%-5%.

Request A Laser Additives Quote for Your Project - Laser-marked White on Colored Polymers

Get an instant quote or let us know what you’re looking for and we’ll get back to you soon!