Manufacturer in China

LASER MARKING ADDITIVE FOR PLASTIC

DOME Materials is a professional Laser Marking Additive manufacturer and wholesale supplier in China.

Check Out Our Selection of Laser Marking Masterbatches for Your Polymers.

- Free Samples

- Fast Delivery

- Customizable

- Competitive Price

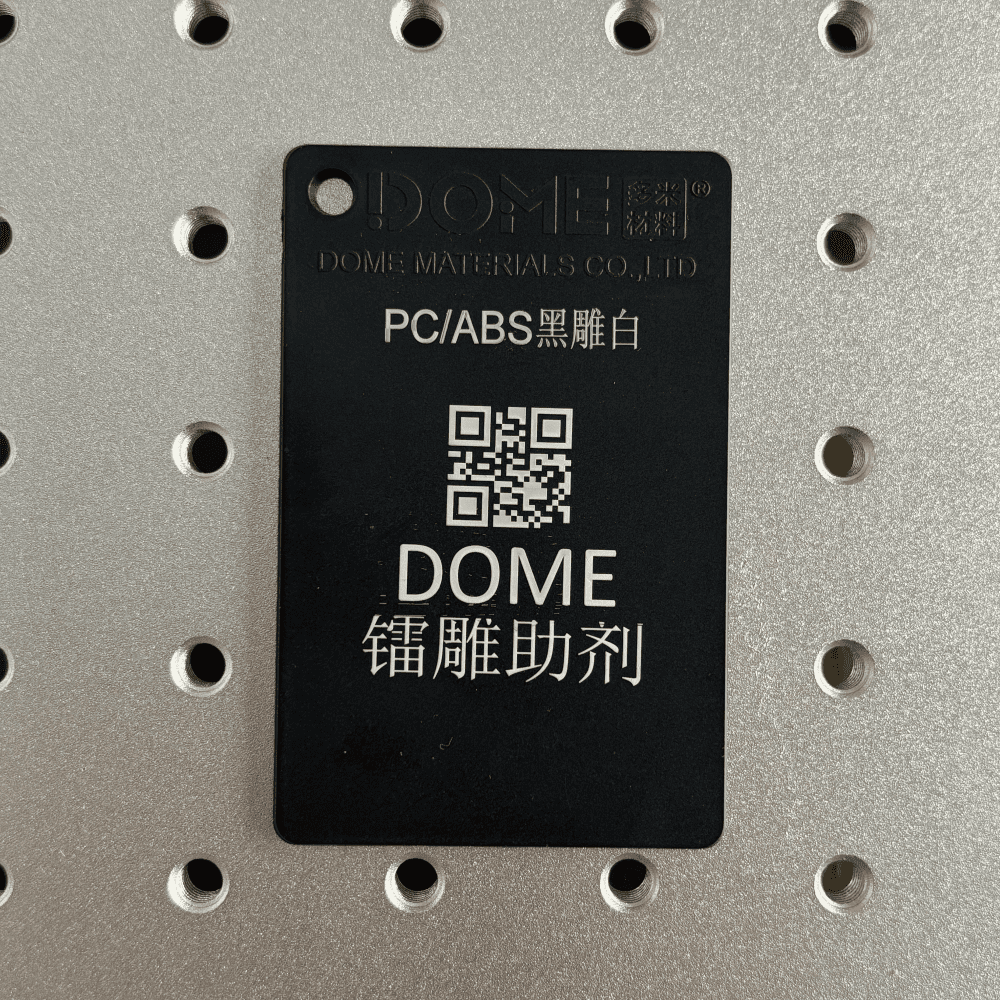

Product Model: DM-GB0031 | DM-GB0041 | DM-GB0051 | DM-GB0061 | DM-GB0151

The laser marking procedure enables permanent markings to be made on plastic surfaces with a visually controlled laser beam. Material optimization with the addition of laser marking additives is often essential for achieving an optimal marking contrast.

The utilization of laser marking additives / laser-sensitive additives for marking white on black plastic is a prevalent practice in everyday life. Examples include keyboards, cables, and electronic product-injected parts. However, please note that only natural or transparent plastic materials should be used when employing this method. The addition of carbon black, black masterbatch, or black toner will have a detrimental effect on the laser marking outcome. It should be noted that our laser marking additive contains carbon black. Overuse of carbon black will impede the absorption of laser light, ultimately diminishing the contrast of the laser marking result. If you find that the blackness is insufficient in the later stages, you may add organic, oily black to deepen the color.

Take Your Business To The Next Level

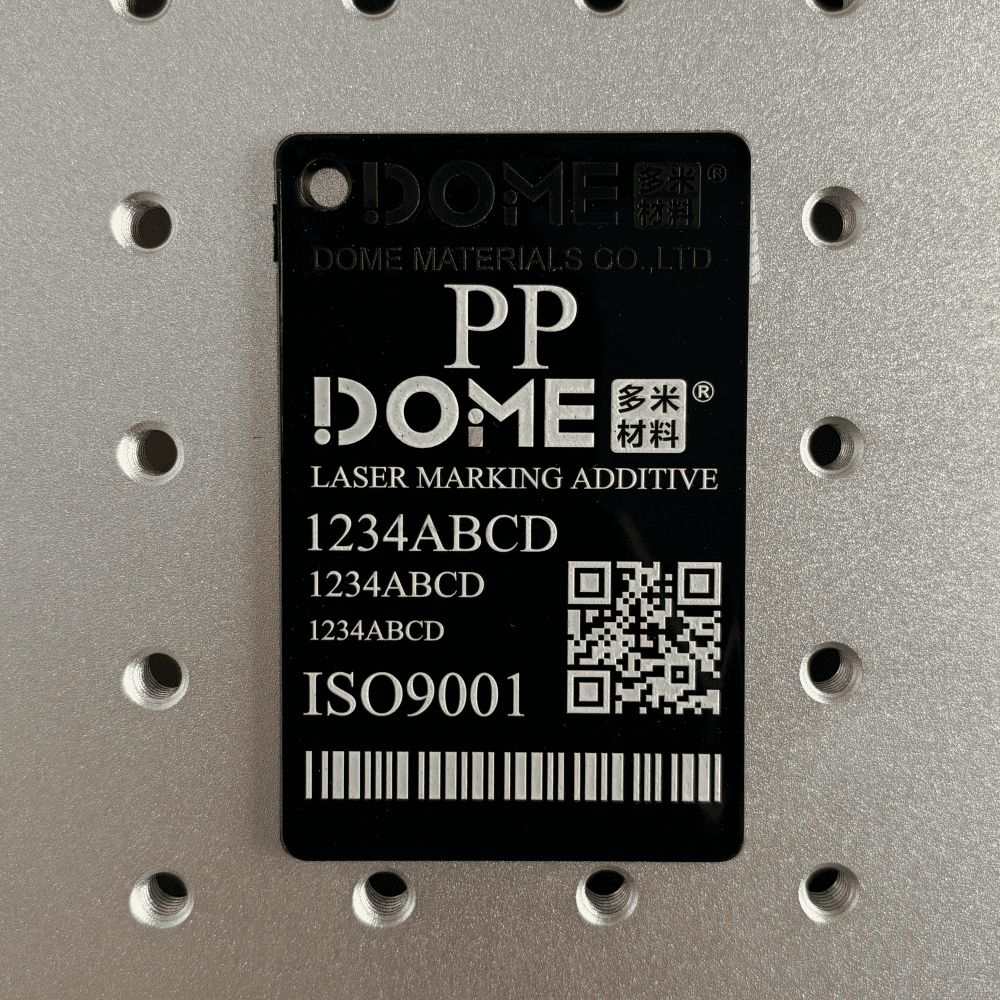

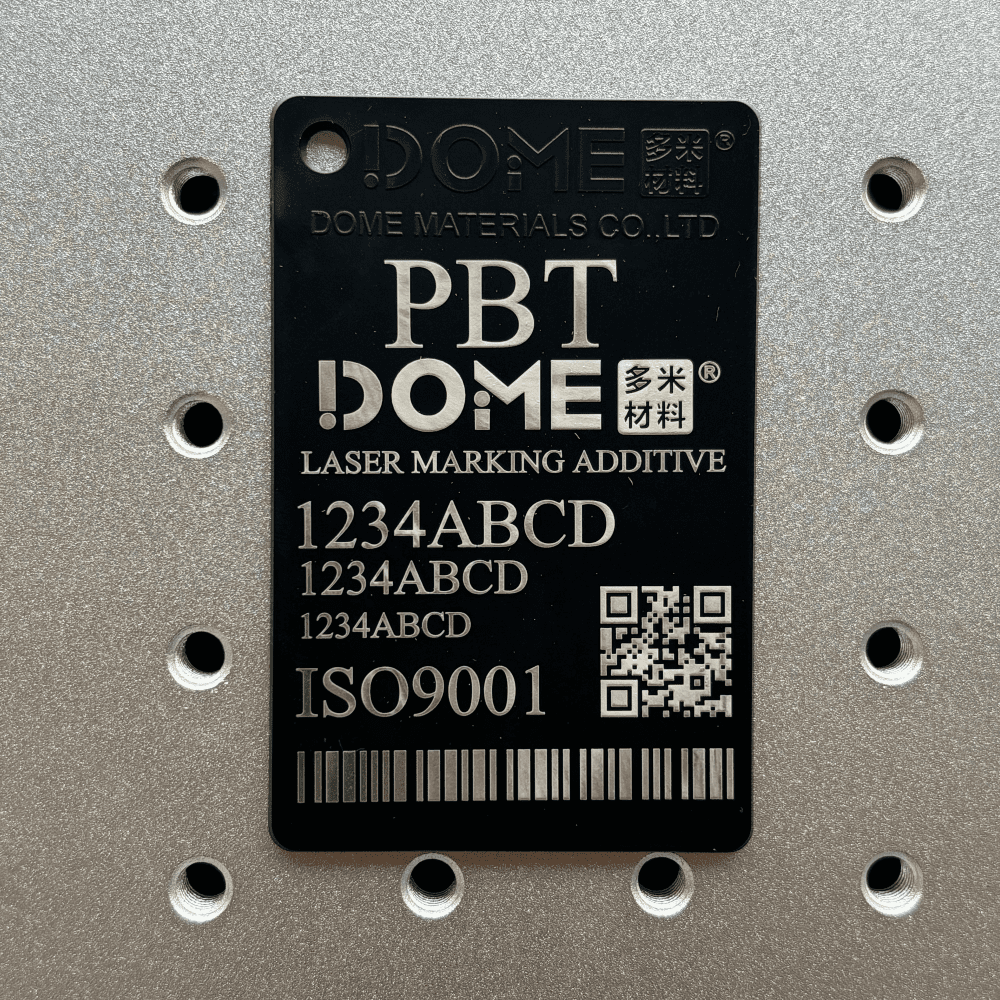

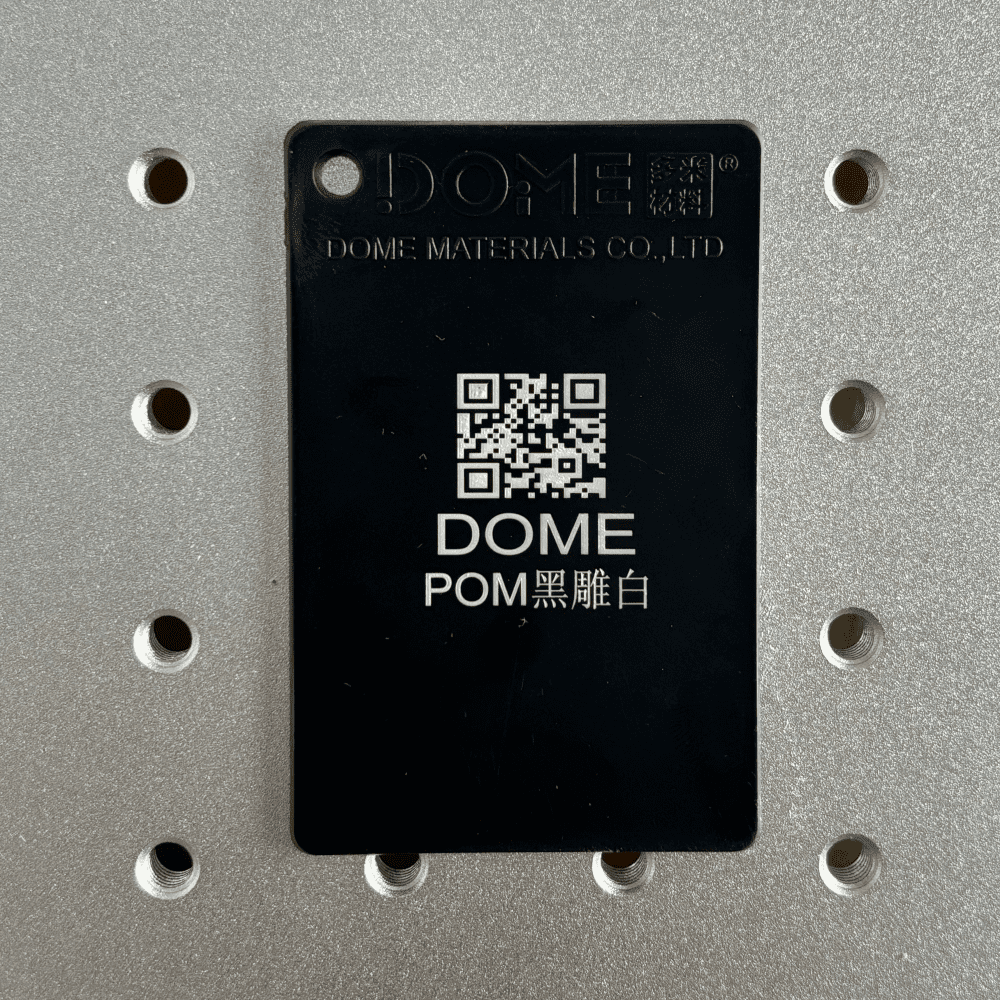

DOME Laser Marking Additives Masterbatch is specifically designed to create high-contrast white marks on black products, enhancing clarity, flexibility, and productivity in manufacturing.

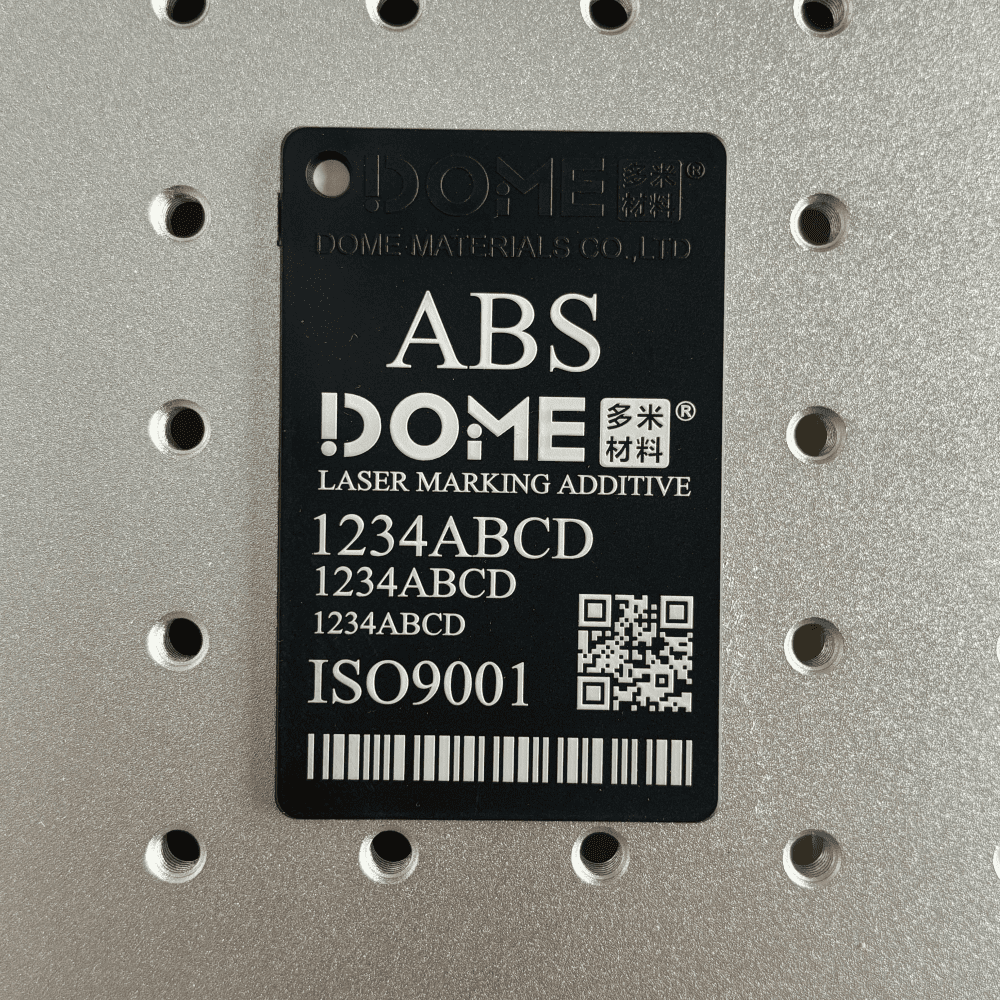

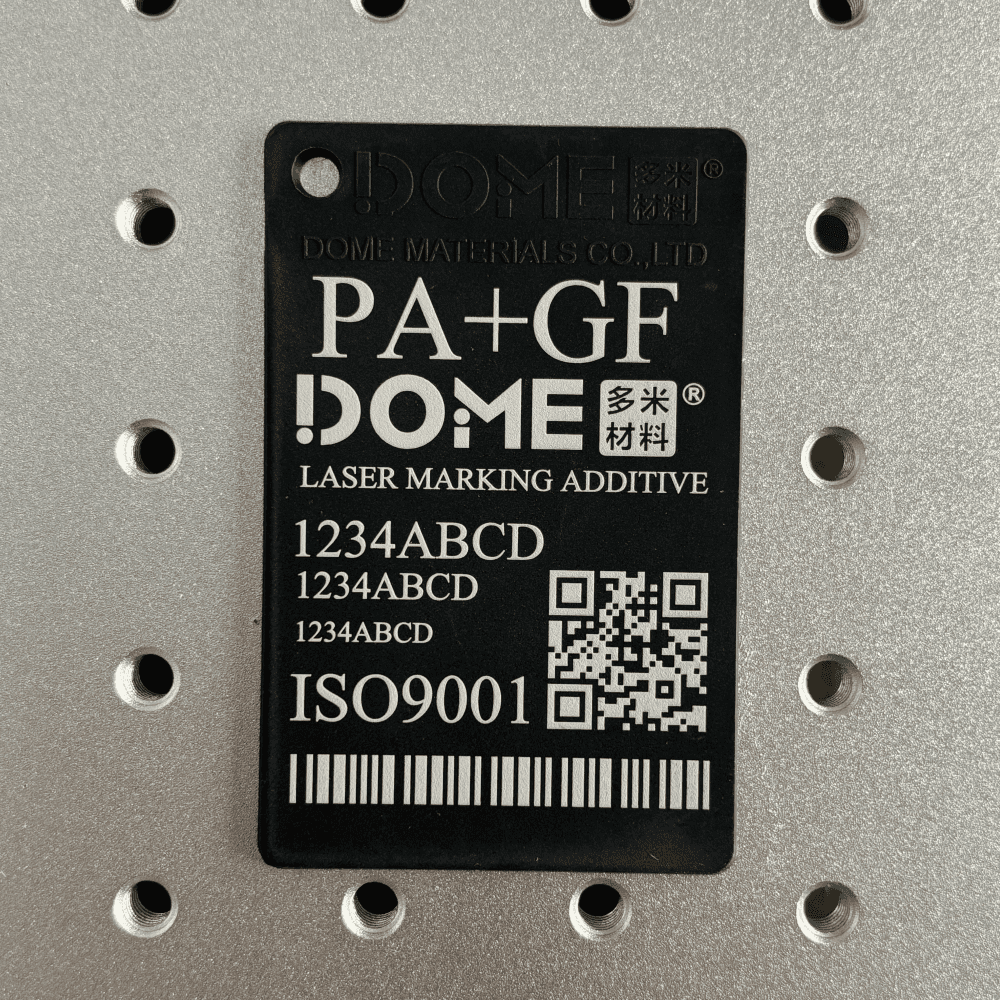

Our laser marking additives are compatible with most polymers and laser types, delivering sharp, clean markings on black plastic parts. The additives are heavy metal-free and safe for food contact applications, making them an excellent choice for a wide range of industries. They achieve impressive line detailing at high speeds, even on plastics that were previously difficult to laser mark.

Important Note: Avoid adding black masterbatches or carbon black during production or injection molding. Our laser-sensitive additive already functions as a black masterbatches, simplifying processes while delivering outstanding results.

Application - Laser-marked White On Black Polymer

The Laser Marking Additives Can be identified in natural color plastic, white plastic, colored plastic, and black plastic laser printing label has been successfully commercialized in applications including TPU livestock ear tags, PP Security Seals, light switch cover, cosmetic packaging materials, 3D Printing Materials, ABS keyboards, HDPE, viz., PET and TPU rigid containers and container lids for automotive interior buttons and door knobs, dashboards, commercial machinery, nylon, and PBT electrical connectors for automotive and non-automotive applications, hood components such as safes and air caps, anti-counterfeiting labels, container latches, stationery, appliance shells and so on.

DOME™ Laser Marking Additives

Top picks Laser-sensitive Additives In Stock: Laser Marking Masterbatch for White Laser on Black Molded Plastic PP, PA, POM, PC, ABS, PBT, PE, and More.

| Product Name | Black Laser-Activated Additive Masterbatch for White Marking on Black Polymer | |||||

| Model No. | DM-GB0031 | DM-GB0041 | DM-GB0051 | DM-GB0061 | DM-GB0141 | DM-GB0151 |

| Resin Compatibility | PP, PE, PA66, TPU, POM, PBT | PC | ABS | PP, PE, POM | PP, PE, PA66, TPU, POM, PBT | PP, PE, PA66, TPU, POM, PBT |

| Dosage | 1-1.5% | 1-1.5% | 1-1.5% | 1-1.5% | 1-1.5% | 1-2% |

| Carrier | PE | PC | ABS | PE | PE | PE |

| Laser Type | Fiber Laser/UV Laser | |||||

| Color | Black | |||||

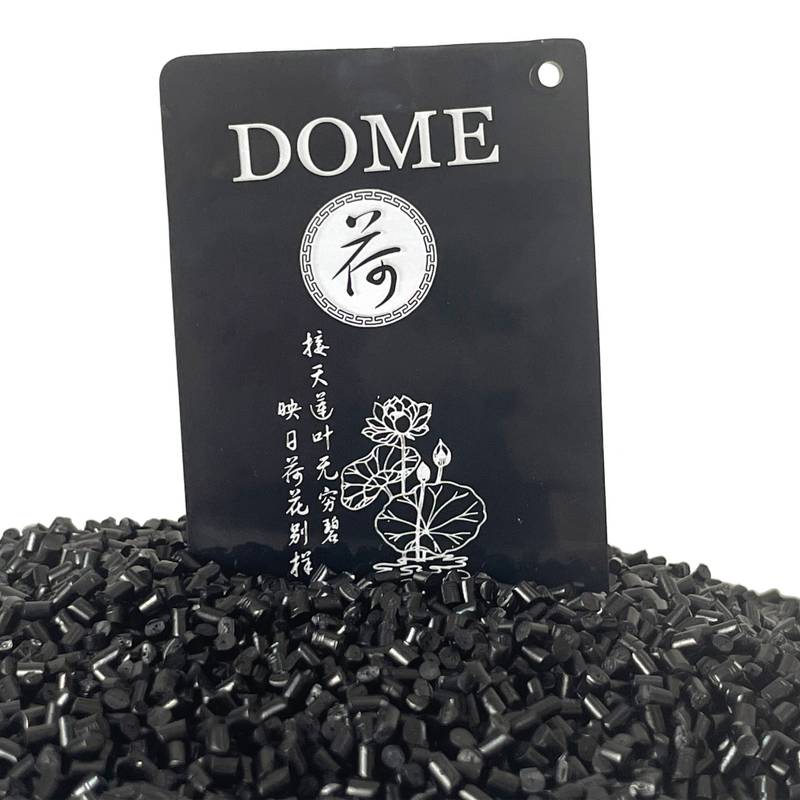

| Apperiance | Granule 2.5-3.0mm | |||||

| Processing Temperature | > 180 °C | |||||

| Drying Temperature | < 90 °C | |||||

| Melt Flowing Rate | 10.0-25.0 (g/10min. 190℃, 5KG) | |||||

| Density(g/cm³) | 8-10g/cm³ | |||||

| Bulk Density(g/cm³) | 90-110g/100ml | |||||

| Heat Stability | Stable up to 280 °C | |||||

| PH Value | 7-11 | |||||

| Certification | ISO9001 MSDS | |||||

| Packing Details | 25KGs/Carton, Carton Size: 580*450*160mm | |||||

| HS No. | 3824999999 | |||||

| CAS No. | 1317-61-9 | |||||

| EINECS No. | 215-175-0 | |||||

| Place of Origin | Shenzhen China | |||||

| Classification | Chemical Auxiliary Agent | |||||

| Brand Name | DOME™ | |||||

Laser Marking Masterbatch - White Laser Mark on Black Products

Wholesale at Competitive Prices

Don’t miss out and take advantage of our factory prices. Check out our catalog and see only the best deals for you and your Polymer laser marking needs. On top of our competitive prices, enjoy huge discounts for bulk orders as well.

In our well-maintained raw material warehouse spanning 1000 square meters, we maintain a consistent and reliable inventory of raw materials. This enables us to minimize the expenses associated with raw material procurement. As the foremost manufacturer of laser marking additives in China, we offer a comprehensive one-stop service. Typically, orders weighing up to 5 tons are swiftly delivered within 1-3 working days, effectively reducing procurement costs and enhancing operational efficiency for our valued customers.

Features and Benefits of Laser Marking for Plastic

- Non-contact processing, durability;

- High precision, fast, high legibility, reliability;

- Forming a top-quality micro mark;

- Environment-friendly;

- Easy to use, strong security features;

- Strong traceability of products;

- High-speed automatic processing can be achieved ;

- The overall production cost of individual parts is far less than that of printing traditional inks.

Black Mark on Color Polymer

White Mark on Black Polymer

White Mark on Color Polymer

Black Mark on Transparent Polymer

White Mark on black Products – Laser Marking Powder

Black Mark on Color Products – Laser Marking Powder

Customized Laser Marking Additives & Custom Modified Compounds

Our laser marking aids are suitable for a variety of plastic materials, such as PE / PP / PC / TPU / ABS / PC+ABS / PBT / HIPS, etc.

We can also provide custom-modified masterbatches upon request. You have the choice between purely laser additive masterbatches or combination masterbatches, consisting of carrier polymer, additives, and the color of your choice. such as modified ABS materials for the ABS keyboard (70% ABS Resin + 30% PMMA +4% Laser Marking Masterbatch), custom modified TPU materials for livestock ear tags (TPU Resin + Laser Marking Additive + Pigment), and modified materials for cables, etc.

We do not require a minimum order quantity for the laser marking additives, so you can buy according to the actual needs of your project, no need to make an additional inventory.

Package and Storage

- Caton Size: 500*380*160mm | 420*380*160mm

- Weight: 25Kgs/carton | 20Kgs/carton

- Laser additive is packaged in a plastic box or a carton lined with a PE bag;

- Laser additive is non-dangerous goods;

- Please store in dry and ventilated conditions;

- Waterproof and moisture-proof;

- Avoid sun exposure;

- Please seal the unused portion of the Laser additive;

- Please use it up within 24 months.

- DELIVERY: 1-3 working days under 5000Kgs, 5-7 working days for Biger Order

Frequently Asked Questions

This section contains a few FAQs that our customers ask. If your question is not here, contact us today, and we will answer directly.

How does the absence of a baking step impact the effectiveness of the laser additive in the injection molding process?

In plastic injection molding and granulation processes, laser additives should be thoroughly mixed with the raw materials. Typically, these can be baked together with the raw materials. However, if the raw materials, such as PP and PE used in injection molding, do not require baking, additional baking is unnecessary. In this case, the laser additive can be directly incorporated into the injection molding process.

What type of laser machine do I need if I want to laser mark white marks on my black plastic products?

We usually recommend fiber laser machines, which have the advantages of fast marking speed and one-time marking, low energy consumption, long life, and low operating costs. Of course, UV laser machines are also available, but compared to fiber laser machines, the overall cost will be much higher.

Can one laser additive be used on various plastic materials?

The DM-GW0032 laser additive developed by DOME is a versatile solution that can be utilized on various plastic materials including PP, PE, PC, and TPU, etc. However, we typically recommend matching customers with additives that are specially formulated for their specific materials and laser marking requirements to achieve the most optimal marking effect. For instance, we offer laser additive specifically designed for ABS keyboard materials as well as laser marking additive suitable for PE/TPV cables.

Why can't I add carbon black masterbatch/toner when laser marking white on black plastic?

In the application of laser marking white on black plastic products, we request to avoid adding any carbon black masterbatch/toner pigment during the injection molding process, but directly replace the black masterbatch with 1%-2% laser marking additives, because too much carbon black will affect the absorption of laser and affect the effect of laser marking.

Request A Laser Additives Quote for Your Project - Laser White Mark on Black Polymers

Get an instant quote or let us know what you’re looking for and we’ll get back to you soon!