Manufacturer in China

LASER MARKING ADDITIVE FOR PLASTIC

DOME Materials is a professional Laser Marking Additive manufacturer and wholesale supplier in China.

Check Out Our Selection of Laser Marking Masterbatches for Your Polymers.

- Free Samples

- Fast Delivery

- Customizable

- Competitive Price

Product Model: DM-PW0036 | DM-PW0046 | DM-PW0056HE

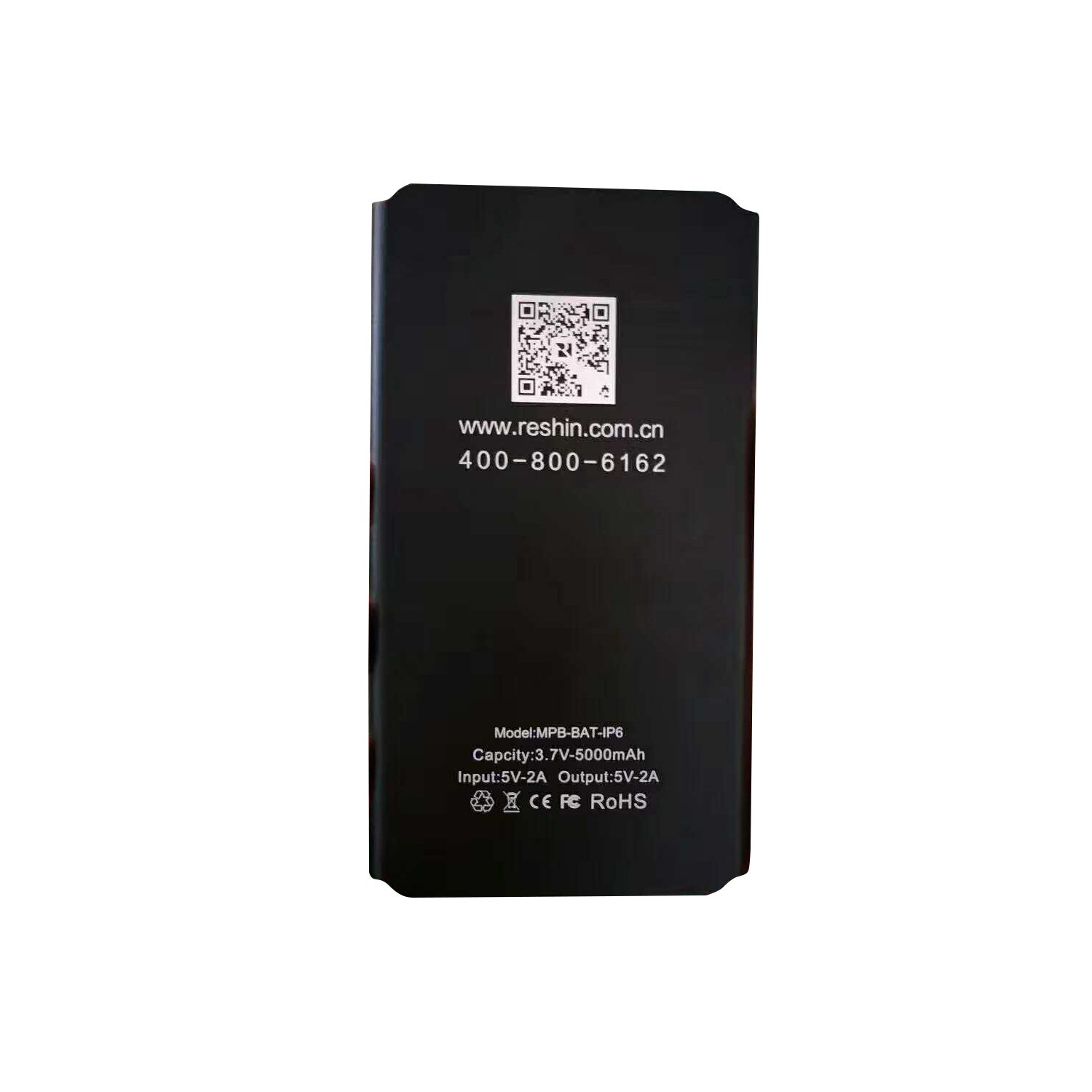

Our laser marking powder is the perfect solution for achieving a White mark on black plastic products! Our powder is specially designed for use with laser marking technology, allowing for precise and long-lasting results.

Whether you’re looking to add product information, branding, or unique identification to your black plastic products, our laser marking powder is the ideal choice. With its high-quality, durable finish, your marks will remain legible and vibrant even after rigorous use and exposure to the elements.

Our laser marking powder is easy to use and compatible with fiber or UV laser marking machines, making it the perfect choice for businesses of all sizes. Plus, with its cost-effective factory wholesale pricing, you can achieve professional-grade marking results without breaking the bank.

So why wait? Try our laser marking powder today and take your black plastic product marking to the next level!

Take Your Business To The Next Level

DOME offers a comprehensive range of laser marking additives specifically designed to optimize results for each polymer formulation. Laser marking is a highly effective method for creating permanent and indestructible marks on plastic surfaces, offering a range of advantages over other marking techniques. These include enhanced quality control, brand protection against counterfeiting, and resistance to environmental factors. The versatility of laser marking makes it suitable for both high-volume production and small batch sizes. It can be applied on surfaces of varying hardness and even on non-flat surfaces, allowing for marking in all three dimensions. Whether for technical applications such as bar codes and lot numbers or for decorative purposes, laser marking is a reliable and durable solution. However, it’s important to note that not all polymers react the same way to laser marking. Some, like PE or PP, are nearly transparent to the commonly used near-infrared lasers with a wavelength of around 1064 nm. In contrast, polymers like PC easily interact with NIR laser light without the need for additives. Therefore, the use of laser marking additives is often necessary to achieve optimal results in many polymer types.

Application-Laser-marked White On Black Polymer

Promotion codes embedded in beverage caps, barcodes, and QR codes are some of the diverse laser marking applications available. Laser marking proves incredibly useful for imprints on food and cosmetics packaging, incorporating logos, scales, product information, expiry dates, and decorative designs. Additionally, laser marking provides a reliable method for marking animal ear tags, safety seals, and security tags to ensure authenticity and prevent plagiarism. This innovative technique is also commonly used to imprint keyboards, interior and exterior automotive accessories, as well as cables and pipes. When it comes to electronic components, medical products, and laboratory equipment, laser marking offers unparalleled precision and durability.

DOME™ Laser Marking Additives

Top-picks In Stock:

|

Product Name |

Model No. | Compatibility | Dosage |

Laser Type |

| Laser Marking Masterbatch – Black Mark on Color Plastic | DM-GW0032 | Universal | 1-5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) |

| DM-GW0042 | PP | 1-5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-GW0052 | PC | 1-5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-GW0062 | Universal | 1-4% | UV Laser(355nm), Green Laser(532nm) | |

| Laser Marking Masterbatch – White Mark on Black Plastic | DM-GB0031 | Universal | 0.5-0.6% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) |

| DM-GB0041 | PC | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-GB0051 | ABS | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-GB0061 | Universal | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| Laser Marking Masterbatch – Black Mark on Transparent Plastic | DM-GB0030 | PP | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) |

| DM-GB0040 | PC | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| Laser Marking Masterbatch – White Mark on Color Plastic | DM-GG0033 | Universal | 1-3% | UV Laser(355nm), Green Laser(532nm) |

| Laser Marking Powder – Black Mark on Color Plastic | DM-PW0036 | Universal | 0.2-0.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) |

| DM-PW0046 | ABS | 0.2-0.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-PW0056HE | PBT | 0.1-0.3% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| Laser Marking Powder – White Mark on Black Plastic | DM-PB0037 | Universal | 0.2-0.5% | UV Laser(355nm), Green Laser(532nm) |

Laser Marking Powder - Laser-marked White On Black Polymer

Wholesale at Competitive Prices

Don’t miss out and take advantage of our factory prices. Check out our catalog and see only the best deals for you and your Polymer laser marking needs. On top of our competitive prices, enjoy huge discounts for bulk orders as well.

In our well-maintained raw material warehouse spanning 1000 square meters, we maintain a consistent and reliable inventory of raw materials. This enables us to minimize the expenses associated with raw material procurement. As the foremost manufacturer of laser marking additives in China, we offer a comprehensive one-stop service. Typically, orders weighing up to 5 tons are swiftly delivered within 1-3 working days, effectively reducing procurement costs and enhancing operational efficiency for our valued customers.

Features and Benefits of Laser Marking for Plastic

- Non-contact processing, durability;

- High precision, fast, high legibility, reliability;

- Forming a top-quality micro mark;

- Environment-friendly;

- Easy to use, strong security features;

- Strong traceability of products;

- High-speed automatic processing can be achieved ;

- The overall production cost of individual parts is far less than that of printing traditional inks.

Black Mark on Color Polymer

White Mark on Black Polymer

White Mark on Color Polymer

Black Mark on Transparent Polymer

White Mark on black Products – Laser Marking Powder

Black Mark on Color Products – Laser Marking Powder

Customized Laser Marking Additives & Custom Modified Compounds

Our laser marking aids are suitable for a variety of plastic materials, such as PE / PP / PC / TPU / ABS / PC+ABS / PBT / HIPS, etc.

We can also provide custom-modified masterbatches upon request. You have the choice between purely laser additive masterbatches or combination masterbatches, consisting of carrier polymer, additives, and the color of your choice. such as modified ABS materials for the ABS keyboard (70% ABS Resin + 30% PMMA +4% Laser Marking Masterbatch), custom modified TPU materials for livestock ear tags (TPU Resin + Laser Marking Additive + Pigment), and modified materials for cables, etc.

We do not require a minimum order quantity for the laser marking additives, so you can buy according to the actual needs of your project, no need to make an additional inventory.

Package and Storage

- Caton Size: 500*380*160mm | 420*380*160mm

- Weight: 25Kgs/carton | 20Kgs/carton

- Laser additive is packaged in a plastic box or a carton lined with a PE bag;

- Laser additive is non-dangerous goods;

- Please store in dry and ventilated conditions;

- Waterproof and moisture-proof;

- Avoid sun exposure;

- Please seal the unused portion of the Laser additive;

- Please use it up within 24 months.

- DELIVERY: 1-3 working days under 5000Kgs, 5-7 working days for Biger Order

Frequently Asked Questions

This section contains a few FAQs that our customers ask. If your question is not here, contact us today, and we will answer directly.

To ensure optimal laser marking results of black plastic products, it is crucial to refrain from incorporating carbon black masterbatch/toner during the injection molding process. By substituting the black masterbatch with laser marking additives comprising 1%-2%, the negative impact on laser absorption caused by excessive carbon black content is mitigated. This precautionary step is essential for maintaining the desired laser marking effect.

What Are the Differences Between Laser Marking, Laser Engraving, and Laser Etching?

Laser marking is a method for creating permanent marks on surfaces, laser engraving involves removing material to create deep and precise marks, and laser etching refers to a lighter mark achieved by partially removing the surface layer. The choice between these techniques depends on the desired result, material type, and specific application.

What should be paid attention to when using laser marking powder?

Firstly, it is important to note that the specific gravity of laser marking powder is usually higher than that of plastic masterbatch. Consequently, during the mixing and usage process, laser marking powder often tends to sink to the bottom. This can result in uneven dispersion, ultimately affecting the desired laser marking effect.

To address this issue, it is generally recommended to use laser marking powder in the production process of extrusion granulation. This ensures a more efficient and effective distribution of the powder throughout the material. However, in cases where direct injection molding is preferred, it is best to utilize laser marking masterbatch. This helps to overcome the challenge of uneven dispersion typically associated with laser marking powder.

Why Does Your Business Need Laser Marking?

Laser marking provides businesses with a reliable and versatile solution for product identification, traceability, compliance, and customization, ultimately enhancing brand value and customer satisfaction.

Related products

-

Laser Marking Masterbatch- Laser-marked Black on Clear PC PP Polymer

Read more -

Laser Marking Powder | Laser-marked Black On Colored Polymer

Read more -

Laser Marking Additive Masterbatch-Laser-marked White On Black Polymer

Read more -

Laser Marking Additive Masterbatches | Laser-marked White On Colored Polymer

Read more

Request A Laser Marking Powder Quote for Your Project - Laser White Mark on Black Polymers

Get an instant quote or let us know what you’re looking for and we’ll get back to you soon!