Manufacturer in China

LASER MARKING ADDITIVE FOR PLASTIC

DOME Materials is a professional Laser Marking Additive manufacturer and wholesale supplier in China.

Check Out Our Selection of Laser Marking Masterbatches for Your Polymers.

- Free Samples

- Fast Delivery

- Customizable

- Competitive Price

Product Model: DM-PB0037

Our laser marking powder – a black mark on color products developed to provide exceptional marking results on colored plastic products, this solution is perfect for a range of industries, from automotive and electronics to medical and aerospace.

Our laser marking powder is extremely durable, making it the ideal choice for products that require long-lasting identification. Not only does it offer superior quality, but it’s also incredibly cost-effective, making it a practical choice for both small and large-scale productions.

With our laser marking powder, you can easily differentiate your products and establish your brand identity with precision and clarity. Its application is effortless and efficient, saving you time and increasing productivity.

Choose our laser marking powder for superior results, durable performance, and unbeatable value. Experience the difference today!

Take Your Business To The Next Level

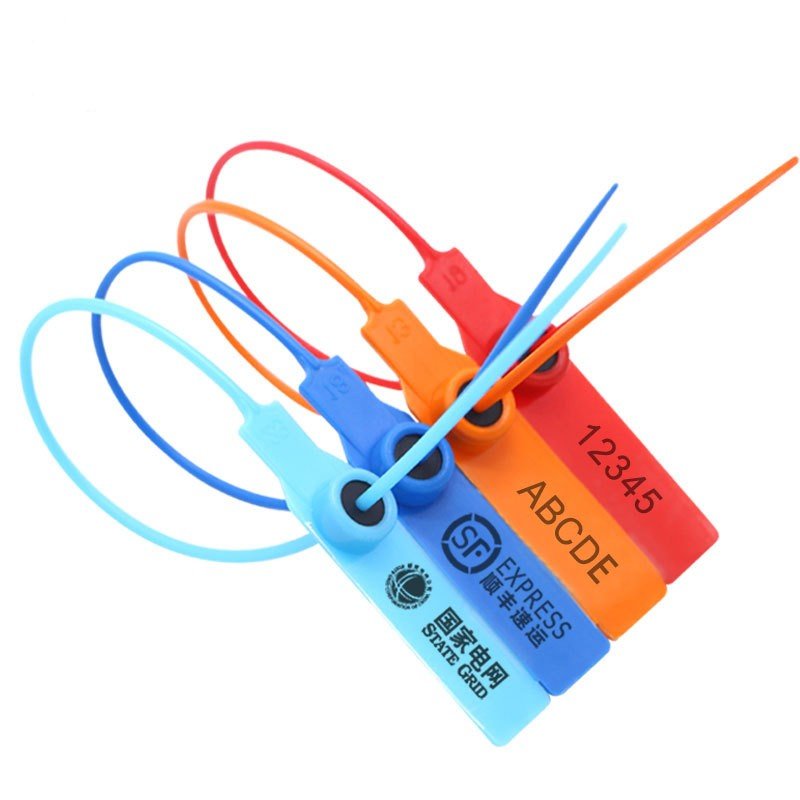

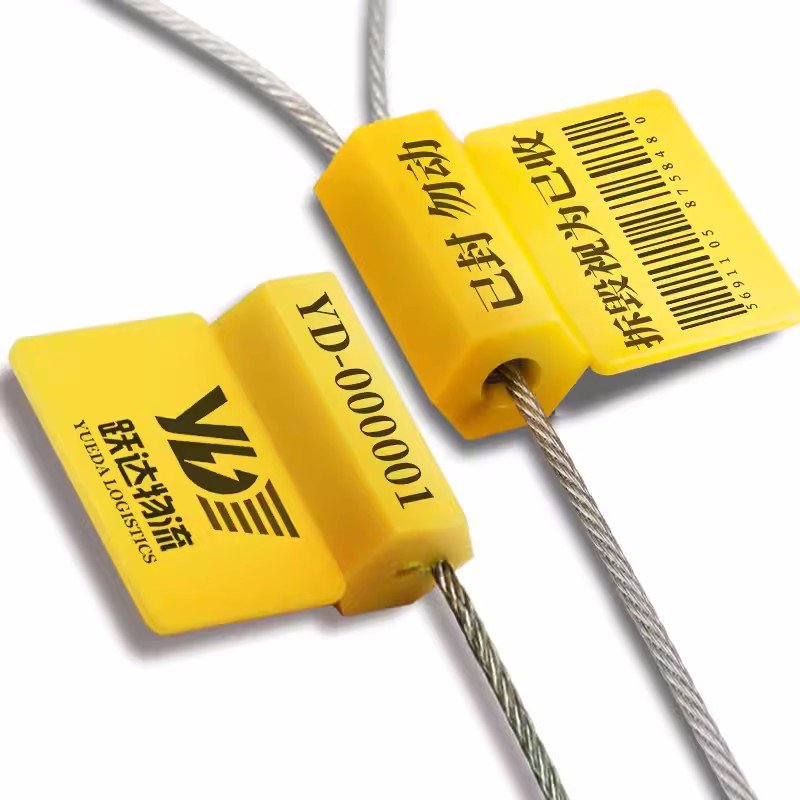

Revolutionize the way you mark your PP security seal tags and ABS lead seals with our innovative Laser Marking Powder! Our powder solution creates a high-quality black mark on colored polymers, offering a reliable and long-lasting marking solution for your business needs. At DOME Materials, we specialize in providing plastic laser marking solutions that meet the unique requirements of your industry. Trust us to deliver the best results every time!

Application-Laser-marked Black On Colored Polymer

Looking for a reliable laser marking solution? Our company offers laser marking solutions for various sectors and applications.

In the automotive industry, we can help you defend warranty claims from non-OEM parts fitted by laser marking lot numbers and manufacture dates directly onto your parts.

For interior decoration, we can use laser marking to make your products even more appealing.

In the electronics industry, we provide laser marking additives for part identification on keyboards, control switches, and some components. For cosmetics and personal care products, our laser marking Additives can help you with part decoration, logos, personalization, use-by dates, and promotional codes. We also offer laser marking Additives for caps and closures, including barcodes, decoration, logos, use-by dates, and anti-counterfeiting.

If you’re in the food packaging industry, laser mark caps with barcodes, decorations, logos, use-by dates, and promotional codes.

For agriculture, we can help permanently mark livestock ID tags for tracking and identification purposes.

In the medical industry, we can provide laser marking for single-use items to comply with recent changes in medical standards requiring identification with lot/ID numbers.

Partner with us for reliable and high-quality laser marking solutions that meet your specific needs. Contact us today to learn more and request a quote.

DOME™ Laser Marking Additives

Top-picks In Stock:

| Product Name | Model No. | Compatibility | Dosage | Laser Type |

| Laser Marking Masterbatch – Black Mark on Color Plastic | DM-GW0032 | Universal | 1-5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) |

| DM-GW0042 | PP | 1-5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-GW0052 | PC | 1-5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-GW0062 | Universal | 1-4% | UV Laser(355nm), Green Laser(532nm) | |

| Laser Marking Masterbatch – White Mark on Black Plastic | DM-GB0031 | Universal | 0.5-0.6% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) |

| DM-GB0041 | PC | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-GB0051 | ABS | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-GB0061 | Universal | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| Laser Marking Masterbatch – Black Mark on Transparent Plastic | DM-GB0030 | PP | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) |

| DM-GB0040 | PC | 1-1.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| Laser Marking Masterbatch – White Mark on Color Plastic | DM-GG0033 | Universal | 1-3% | UV Laser(355nm), Green Laser(532nm) |

| Laser Marking Powder – Black Mark on Color Plastic | DM-PW0036 | Universal | 0.2-0.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) |

| DM-PW0046 | ABS | 0.2-0.5% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| DM-PW0056HE | PBT | 0.1-0.3% | Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm) | |

| Laser Marking Powder – White Mark on Black Plastic | DM-PB0037 | Universal | 0.2-0.5% | UV Laser(355nm), Green Laser(532nm) |

Laser Marking Powder - Laser-marked Black On Colored Polymer

Wholesale at Competitive Prices

Don’t miss out and take advantage of our factory prices. Check out our catalog and see only the best deals for you and your Polymer laser marking needs. On top of our competitive prices, enjoy huge discounts for bulk orders as well.

In our well-maintained raw material warehouse spanning 1000 square meters, we maintain a consistent and reliable inventory of raw materials. This enables us to minimize the expenses associated with raw material procurement. As the foremost manufacturer of laser marking additives in China, we offer a comprehensive one-stop service. Typically, orders weighing up to 5 tons are swiftly delivered within 1-3 working days, effectively reducing procurement costs and enhancing operational efficiency for our valued customers.

Features and Benefits of Laser Marking for Plastic

- Non-contact processing, durability;

- High precision, fast, high legibility, reliability;

- Forming a top-quality micro mark;

- Environment-friendly;

- Easy to use, strong security features;

- Strong traceability of products;

- High-speed automatic processing can be achieved ;

- The overall production cost of individual parts is far less than that of printing traditional inks.

Black Mark on Color Polymer

White Mark on Black Polymer

White Mark on Color Polymer

Black Mark on Transparent Polymer

White Mark on black Products – Laser Marking Powder

Black Mark on Color Products – Laser Marking Powder

Customized Laser Marking Additives & Custom Modified Compounds

Our laser marking aids are suitable for a variety of plastic materials, such as PE / PP / PC / TPU / ABS / PC+ABS / PBT / HIPS, etc.

We can also provide custom-modified masterbatches upon request. You have the choice between purely laser additive masterbatches or combination masterbatches, consisting of carrier polymer, additives, and the color of your choice. such as modified ABS materials for the ABS keyboard (70% ABS Resin + 30% PMMA +4% Laser Marking Masterbatch), custom modified TPU materials for livestock ear tags (TPU Resin + Laser Marking Additive + Pigment), and modified materials for cables, etc.

We do not require a minimum order quantity for the laser marking additives, so you can buy according to the actual needs of your project, no need to make an additional inventory.

Package and Storage

- Caton Size: 500*380*160mm | 420*380*160mm

- Weight: 25Kgs/carton | 20Kgs/carton

- Laser additive is packaged in a plastic box or a carton lined with a PE bag;

- Laser additive is non-dangerous goods;

- Please store in dry and ventilated conditions;

- Waterproof and moisture-proof;

- Avoid sun exposure;

- Please seal the unused portion of the Laser additive;

- Please use it up within 24 months.

- DELIVERY: 1-3 working days under 5000Kgs, 5-7 working days for Biger Order

Frequently Asked Questions

This section contains a few FAQs that our customers ask. If your question is not here, contact us today, and we will answer directly.

When selecting between laser marking powder and laser marking masterbatch, it’s essential to consider their physical forms and material compositions. Laser marking masterbatch is a granular additive that can be easily dispersed during the injection molding process, resulting in a uniform marking effect. However, a higher amount of masterbatch needs to be added (0.6%-5%). Laser marking powder, however, requires a lower addition amount (0.3%-0.5%), making it more cost-effective. However, it needs to be granulated before use to ensure uniform dispersion. In summary, laser marking masterbatch is easier to disperse but requires more, while laser marking powder is more cost-effective but needs to be granulated before use.

Can you ship laser marking powder to my country?

Yes, we have long-term and stable cooperation with international freight forwarders who can transport powder products. Our laser marking additives have relevant MSDS test reports and transportation appraisal reports to ensure that the products can arrive safely.

What are the key factors affecting plastic laser marking?

The contrast and readability of plastic laser marking are influenced by various factors, including the presence of additives, their concentration, laser parameters, and the type of plastic. Additives can significantly impact the final result, but their influence varies depending on other factors. Controlling the additive concentration is crucial for achieving desired results. Laser parameters such as power, beam quality, and marking speed need to be optimized to enhance contrast and readability. Different plastic types have varying characteristics that affect laser marking performance. Therefore, conducting tests tailored to each plastic-additive combination is necessary. Overall, achieving desired results requires careful consideration of these factors and optimizing the laser marking process through testing.

Can laser marking powder be used together with other plastic functional additives?

Yes, DOME™ laser marking additives/laser powder can be used together with other plastic functional additives such as PMMA, anti-UV additives, antistatic additives, flame retardants, glass fibers, etc.

Request A Laser Marking Powder Quote for Your Project - Laser Black Mark on Colored Polymers

Get an instant quote or let us know what you’re looking for and we’ll get back to you soon!