Laser marking technology is increasingly prevalent in the plastic processing industry due to its efficiency, precision, and eco-friendly nature, making it a preferred method for modern manufacturing. However, plastics often have limited laser absorption capabilities, which is where laser marking additives come in as an ideal solution. This article explores the types, applicable materials, marking effects, and usage methods of plastic laser marking additives, providing a comprehensive understanding of their significance and value in plastic processing.

What Are Plastic Laser Marking Additives?

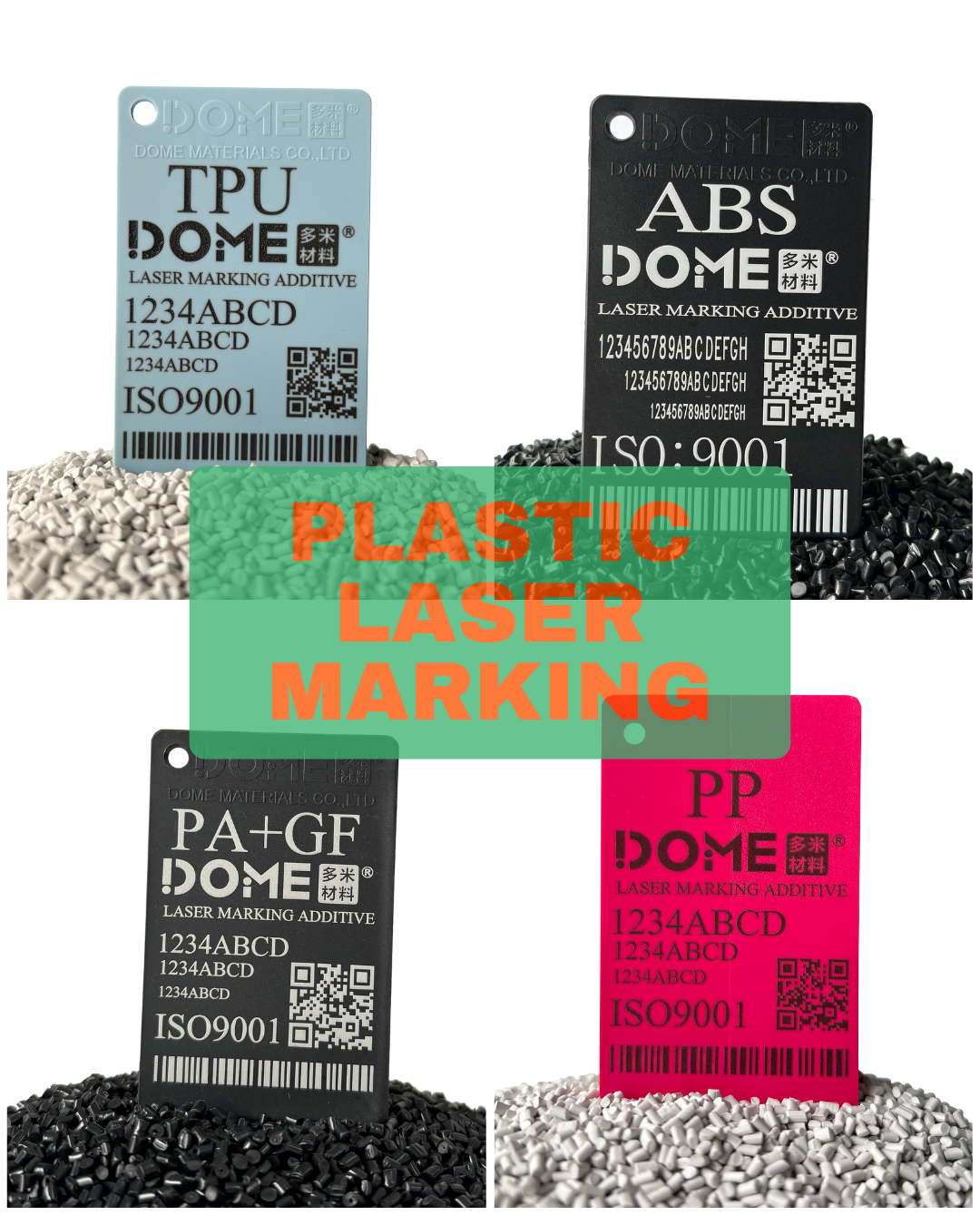

Plastic laser marking additives are specialized compounds designed to enhance the laser marking performance of plastics. By incorporating small amounts of these additives, plastics can better absorb specific wavelengths of laser energy, resulting in clear and durable markings on their surfaces. These additives are widely used in various engineering and modified plastics, compatible with processes like injection molding and extrusion. Common types include laser powder (laser marking powder, laser marking pigment), laser masterbatch, and specialty functional additives, each with unique compositions and applications.

Laser Marking Powder (Laser Marking Pigment): Versatile Marking Solution

Composition and Characteristics

Laser marking powder, also known as laser marking pigment, typically consists of activated carbon as the primary absorbent, combined with additives such as hydroxides, tin oxide, calcium carbonate, metallic antimony, brominated flame retardants, and dispersants. These components enable efficient laser energy absorption, producing clear markings on plastic surfaces.

Applicable Materials

Laser powder is compatible with a wide range of plastics, including PP, PC, PE, ABS, TPU, PA6, PBT, POM, TPE, TPV, TPR, PET, and other engineering plastics, as well as coatings, inks, paints, and unsaturated resins. Its broad compatibility makes it a top choice across industries.

Marking Effects

Laser powder enables markings in black, white, gold, gray, and even colored patterns. Depending on the plastic’s chemical properties and background color, it can produce light markings on dark backgrounds or dark markings on light backgrounds, catering to diverse design needs.

Usage Method

The typical addition ratio for laser powder is 0.1%-0.5%. It can be directly mixed with plastic pellets or pigment powders and processed using injection molding or extrusion equipment. Its low addition rate and high efficiency offer significant cost advantages.

Laser Marking Masterbatch: High-Performance Marking Additive

Composition and Characteristics

Laser marking masterbatch comprises photosensitizers, white or black pigments, and organic polymer carriers. The photosensitizer is the key component, capable of strongly absorbing specific laser wavelengths (e.g., 10.64μm), enhancing marking performance.

Applicable Materials

Laser masterbatch is suitable for plastics such as PP, PE, ABS, PA6, PA66, PS, PBT, PET, POM, SEBS, TPU, and TPE. Its high compatibility makes it widely used in electronics, automotive parts, and medical devices.

Marking Effects

Laser masterbatch supports a variety of marking effects, including black-on-white, white-on-black, color-on-black, gray-on-white, and transparent-on-black. This versatility makes it ideal for complex marking requirements.

Usage Method

The typical addition ratio is 1%-3%. It can be mixed with target plastics for granulation via extrusion or directly combined with materials for injection molding. Additionally, laser masterbatch can be used alongside color masterbatches, dyes, or pigments to enhance visual effects.

Specialty Functional Additives: Innovation and Customization

Coloring Additives

Coloring additives possess inherent colors and, when exposed to laser energy, trigger chemical reactions in the plastic or additive, resulting in color changes for marking. Additives containing metal elements can produce metallic sheen markings, ideal for high-end applications like consumer electronics casings or decorative plastic products.

Foaming Additives

Foaming additives absorb laser energy and rapidly decompose, releasing gases that cause localized foaming and expansion in the plastic. This creates markings with distinct color and texture compared to non-foamed areas. For instance, additives with organic foaming agents generate micro-bubbles during laser marking, leading to visible color changes and tactile effects.

Advantages of Laser Marking Additives

- High Efficiency and Precision: These additives significantly improve laser absorption, ensuring clear and durable markings.

- Eco-Friendly and Safe: Unlike traditional printing or labeling, laser marking produces no chemical pollution, aligning with environmental standards.

- Broad Compatibility: Suitable for various plastics and processing methods, meeting diverse industry needs.

- Cost-Effective: Low addition rates deliver excellent results, reducing production costs.

Application Scenarios

Laser marking additives are widely used in automotive parts, electronics, medical devices, and consumer goods packaging. For example, in the automotive industry, they are used for part numbering and branding; in electronics, for serial numbers and patterns on casings. These applications enhance product aesthetics and traceability.

Conclusion

Plastic laser marking additives are revolutionizing the plastic processing industry with their efficiency, eco-friendliness, and versatility. Whether it’s laser powder, laser masterbatch, or specialty functional additives, each offers flexible solutions for diverse applications. As technology advances, these additives will continue to unlock new possibilities across industries. If you’re seeking an efficient plastic marking solution, laser marking additives are the key to making your products stand out!