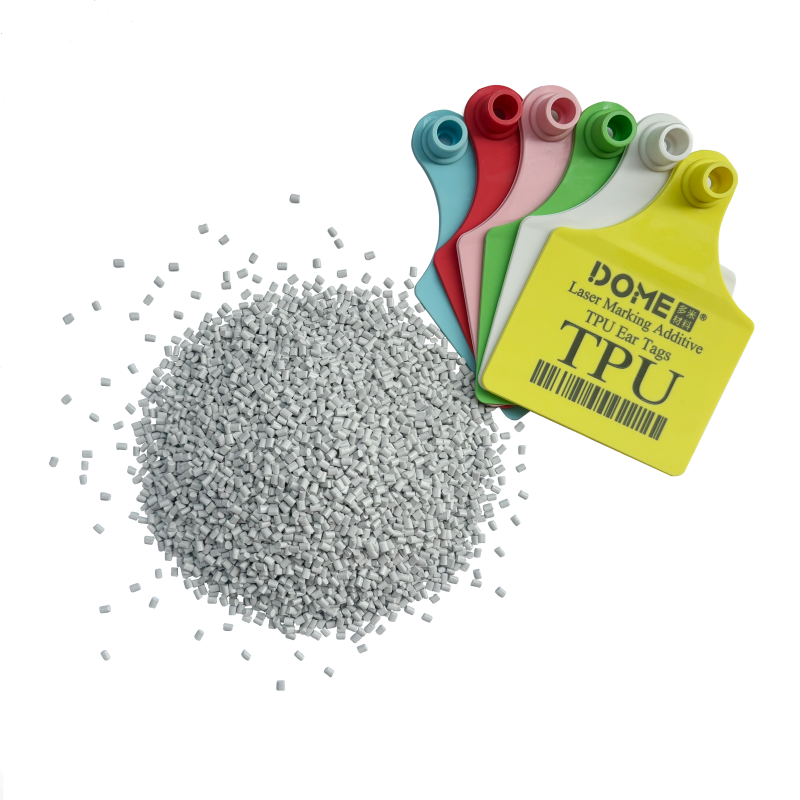

In modern agriculture, livestock identification ear tags have become essential tools for animal traceability and precision farming. As global demands for food safety and animal health tracking intensify, the quality of laser markings on ear tags directly impacts system reliability and regulatory compliance. As a product expert at Shenzhen Dome Materials Co., LTD., I’ve seen firsthand how our laser marking additives help ear tag manufacturers overcome challenges and boost product competitiveness. This article explores the core requirements for laser marking on livestock ear tags, common industry pain points, and the unique advantages of DOME Materials’ additives and masterbatches designed specifically for TPU/PA/PE ear tags.

Core Requirements for Laser Marking on Livestock Ear Tags

Livestock ear tags are more than just plastic labels—they carry critical data like birth dates, vaccination records, breeding information, and ownership details. For this data to remain reliable long-term, laser markings must meet three key requirements:

- Clarity: Markings need to be sharp and quickly scannable, even in busy farm or slaughterhouse environments. Blurred marks can cause identification failures.

- Wear Resistance: Animals are active, so tags endure constant friction from grazing, fencing, or interactions with other animals.

- Environmental Durability: Markings must resist fading or peeling in extreme conditions, from desert heat to tropical rain.

These standards stem from international regulations like ISO 11784/11785 (RFID animal identification) and regional rules (e.g., the UK’s PAS 66:2009). Non-compliance risks product rejections, fines, or reputational damage.

Industry Pain Points: Three Main Reasons for Blurred or Peeling Marks on Traditional Ear Tags

Many manufacturers still face issues with fuzzy or peeling markings. Based on our global client collaborations, the top challenges are:

- Material Incompatibility: Most ear tags use TPU, PA, or PE, which are naturally insensitive to laser energy. Traditional marking requires high laser power, often causing melting or charring—leading to blurred marks and reduced tag strength.

- Suboptimal Additive Formulations: Generic additives need high dosages (5%+), raising costs and affecting material properties like flexibility or brittleness. Poor chemical bonding also causes easy peeling.

- Poor Compatibility with Lasers and Processes: Standard additives work only with specific lasers (e.g., CO2) and aren’t suited for high-speed injection molding, resulting in inconsistent quality, extra quality checks, and post-processing costs.

These issues increase expenses and jeopardize traceability compliance.

DOME Solution: Advantages of Laser Marking Additives for Livestock Ear Tags

DOME Materials’ laser marking additives are engineered specifically for TPU/PA/PE ear tags, integrating seamlessly into injection molding for efficient, high-quality results. Key benefits include:

1. Low Dosage (1%-3%) for Significant Cost Savings

Our concentrated laser marking masterbatches require just 1%-3% addition (vs. 5%+ for generics). This cuts material use—for a factory producing 1 million tags yearly, costs can drop up to 40%—without altering base resin properties: TPU stays flexible, PA retains impact resistance.

2. Compatibility with Fiber/UV Lasers and Injection Molding

Our additives support common fiber and UV lasers, eliminating equipment upgrades. They mix directly with TPU/PA/PE pellets during molding, skipping post-marking steps for smoother production, better consistency, and shorter lead times.

3. High-Contrast Marks for Traceability Compliance

Optimized for laser absorption, our additives create sharp black-on-white (carbonization) or white-on-black (foaming) marks on light or dark tags. These durable, scannable markings withstand harsh conditions and meet standards from the OIE (World Organisation for Animal Health) and authorities in Europe, Asia, and the Americas.

Case Studies: Real Results from Clients in Egypt and Brazil

Real-world data proves the impact. Here’s how we transformed operations for clients in extreme environments:

- Egyptian Client (Extreme Heat and Sand): Using DM-GW0042 laser marking additive (2% dosage), marks retained 95% clarity after 12 months in 45°C+ heat and abrasion. Costs fell 32%, with zero marking-related rejections.

- Brazilian Client (Strict Export Standards): With DM-GW0082S laser marking masterbatch (1.5% dosage), marks achieved 100% scanability after 18 months, meeting SUASA requirements. Export orders rose 28%, and tag loss rates dropped below 2%.

These successes highlight DOME additives’ excellence in tough conditions.

Selection Guide: Recommended Models for Different Ear Tag Materials

Choosing the right additive is key. We offer tailored options for common materials:

- TPU 95A Ear Tags (Ideal for cattle/sheep—flexible and tear-resistant): DM-GW0082S/DM-GW0042. Dosage: 1.5%-2.5%. Delivers high-contrast marks; compatible with color masterbatches without distortion.

- PA/PE/PP Ear Tags (Cost-effective for pigs): DM-GW0032S Dosage: 1%-2%. Excellent dispersion for consistent large-scale production and fiber lasers.

Pro Tip: Test with your resin and laser settings. We provide free samples and customized recommendations.

Conclusion: Partner with DOME—16 Years of Expertise Serving Clients in 70+ Countries

Shenzhen Dome Materials Co., LTD. has refined laser marking solutions for over 16 years, serving ear tag manufacturers in over 70 countries. From cost-saving low-dosage formulas to durable, compliant marks, our additives and masterbatches address real pain points.

We’re more than a supplier—we’re your partner for tailored solutions with expert support.

If blurred or peeling marks are costing you, contact us today to elevate your livestock ear tags and gain a competitive edge!