I. Market Outlook for Laser Marking Additives: A Blue Ocean in Tech-Driven Industries

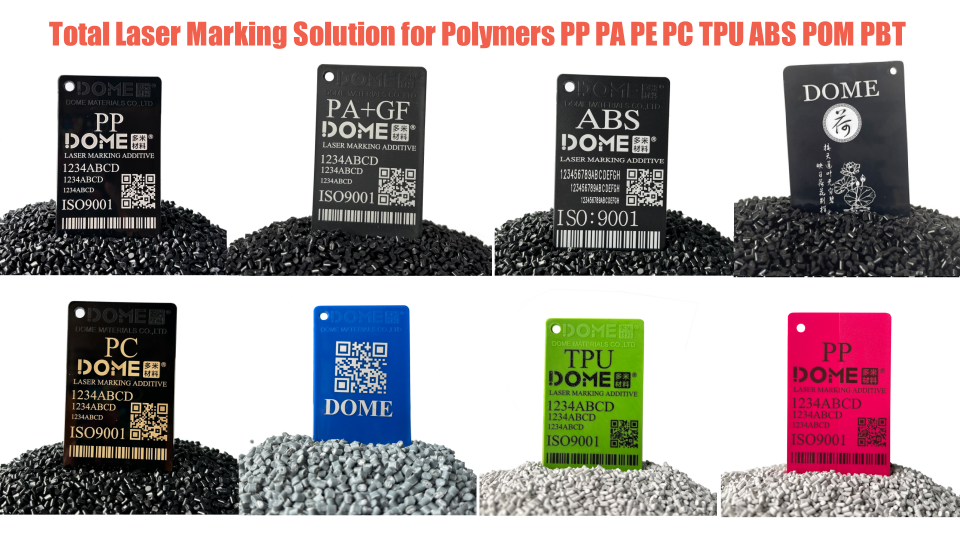

As global manufacturing shifts toward smart, sustainable solutions, laser marking technology—renowned for its non-contact, high-precision, and durable marking capabilities—has become the preferred choice for industrial labeling. Laser marking additives, as the core materials enhancing marking efficiency, are experiencing exponential market growth.

Key Growth Drivers:

- Consumer Electronics: Miniaturization trends drive demand for high-resolution marking on components like circuit boards and chips, emphasizing anti-reflective and high-temperature resistance.

- Medical Devices: Stricter regulations require traceability codes on devices, necessitating additives compatible with biocompatible materials (e.g., polycarbonate).

- New Energy Vehicles: Battery packs and motors need anti-counterfeit and environmental-resistant markings, boosting demand for additives stable under harsh conditions.

- Packaging Industry: Sustainability policies accelerate the adoption of biodegradable plastics (e.g., PLA, PBAT), creating demand for additives tailored to these materials.

- Solar and Energy Storage: Lithium batteries and solar components require UV-resistant, aging-resistant markings, accelerating additive innovation.

- Animal Husbandry and Logistics Industry: Animal identification systems for livestock and animal husbandry, animal ear tags. Plastic security seals and lead seals for the logistics industry.

Industry reports predict the global laser marking additives market will grow at a CAGR of 9.2% from 2023 to 2030, with the Asia-Pacific dominating due to manufacturing upgrades.

II. Five Key Applications in the Plastic Products Industry

Laser marking additives enhance laser energy absorption and conversion, enabling clear, durable markings. Core applications include:

- Embedded Information

• Examples: Batch codes on cosmetic bottles, serial numbers on electronics, production dates on automotive parts.

• Value: Replaces traditional ink printing, eliminates peeling risks, and complies with GDPR-like data regulations. - Brand Value Enhancement

• Examples: Laser-engraved logos on premium appliances, stealth anti-counterfeit markings on luxury packaging.

• Innovation: Transparent plastics paired with specific wavelengths create “stealth markings” for enhanced security. - Functional Marking

• Examples: Circuit diagrams on automotive wiring harnesses, dimension labels on medical catheters.

• Technical Requirements: High-contrast additives ensure readability in extreme environments (e.g., heat, humidity). - Anti-Counterfeiting & Traceability

• Examples: Dynamic QR codes on drug packaging, randomized codes on liquor bottle caps.

• Trend: Integration with blockchain for multi-layered encrypted markings. - Lightweight Design

• Examples: Marking carbon fiber-reinforced plastics (CFRP) and biodegradable packaging.

• Challenge: Balancing material strength with marking depth to avoid structural compromise.

III. Four Critical Considerations When Procuring Laser Marking Additives

With a plethora of products available, businesses must evaluate technical compatibility and long-term costs:

- Material Compatibility

• Key Factor: Ensure additives chemically align with substrates (e.g., PE, PP, ABS, PC) to prevent cracking or bleeding.

• Testing Tip: Request samples for laser parameter optimization trials. - Environmental & Safety Compliance

• Certifications: Must meet RoHS, MSDS, REACH and exclude heavy metals/halogens.

• Special Cases: Food-contact materials require FDA or LFGB certification. - Cost-Benefit Balance

• Pitfall: Low-cost additives may cause blurry markings or rework costs.

• Optimization: Opt for multi-wavelength (CO2, fiber, UV) additives to reduce equipment adaptation expenses. - Technical Support & Service

• Advantage: Suppliers offering free sampling, parameter tuning, and troubleshooting add value.

• Case Study: DOME Materials’ “Marking Lab” simulates client production environments, shortening validation cycles. - Supply Chain Stability

• Risk Mitigation: Prioritize localized production or globally diversified suppliers to avoid disruptions.

IV. Why Choose DOME Materials’ Laser Marking Additives?

Amid fierce competition, DOME Materials stands out with cutting-edge technology and tailored solutions:

- Technology Leadership: Breakthrough Formulations

• Core Products: DomeLase™ series covers visible to near-infrared wavelengths, supporting thin to thick-walled parts.

• Innovation: Proprietary “nanocomposite technology” enhances contrast, even on dark or transparent materials. - Full-Scale Application Adaptability

• Industry Cases:

◦ Automotive: Custom PA66 additives for Tier 1 suppliers, enduring 200°C baking.

◦ Medical: ISO 10993-certified additives for permanent labeling on infusion pumps. - Customized Solutions

• Flexible Formulations: Adjustable particle size and dispersion for injection molding or extrusion.

• Sustainability: REACH-compliant products supporting ESG goals. - Quality Assurance

• Certifications: IATF 16949 certified; marking durability exceeds 500-hour salt spray tests.

• Global Reach: Warehouses in Asia, Europe, and the Americas enable 48-hour urgent delivery. - Collaborative Partnerships

• Cost Efficiency: Bulk purchase discounts paired with free technical support.

• Ecosystem Synergy: Co-develops standardized solutions with laser equipment leaders (e.g., DapengLaser, HansLaser).

V. Conclusion: Embrace Laser Marking Technology for Smarter Manufacturing

Laser marking additives are not just “invisible drivers” of plastic innovation but critical tools for competitiveness and sustainability. Choosing reliable solutions like DOME Materials ensures efficiency, quality, and compliance in an evolving market.

Act Now: Visit DOME Materials for free technical whitepapers and sample kits to revolutionize your laser marking efficiency!