In today’s manufacturing industry, laser marking technology has become essential for the identification, coding, and decoration of plastic products. With ongoing technological advancements, high-performance laser marking machines and specialized plastic laser marking additives are proving to be highly complementary in the field of plastic marking. This article explores how these two innovations can work together to drive the advancement of plastic laser marking technology.

High-Performance Laser Marking Machines: Technological Progress Driving Industry Transformation

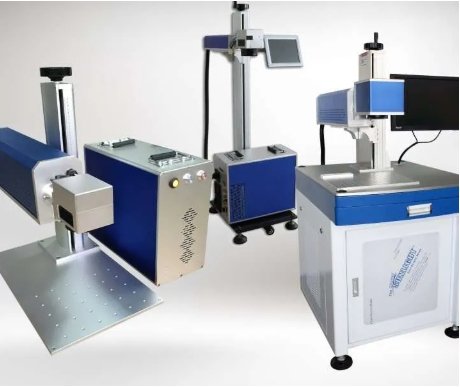

High-performance laser marking machines are reshaping the plastic marking industry. Modern laser marking machines not only offer higher marking precision, achieving micron-level or even sub-micron-level marks, but also meet the demand for high-resolution and quick-scanning codes. For instance, their minimum dot matrix can reach 0.2mm, ensuring high readability of QR codes and barcodes. Moreover, the material adaptability of laser marking machines is constantly improving. By adjusting the laser wavelength and power, they can achieve optimal marking results for various plastic materials such as ABS, PP, and PVC.

The efficiency and environmental friendliness of laser marking machines have also contributed to their widespread application. Their high-speed marking capability significantly enhances production efficiency, completing the marking of a single product in just 2 – 3 seconds and supporting automated production lines. Additionally, as laser marking is a non-contact process, it avoids mechanical damage and internal stress on plastic materials. It also eliminates the need for ink or chemical reagents, reducing environmental pollution.

Plastic Laser Marking Additives: An Indispensable Auxiliary Force

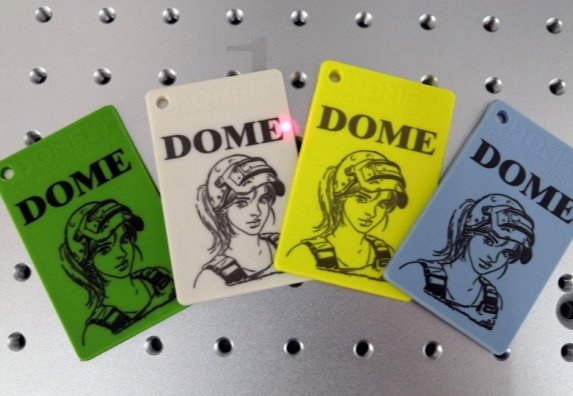

Despite the significant technological advancements in high-performance laser marking machines, plastic laser marking additives still play an irreplaceable role in certain specific scenarios. Many plastic materials, such as resins, ABS, PP, and PE, have poor laser absorption capabilities, making it difficult to achieve clear marks with laser marking machines alone. For example, materials like nylon (polyamide) typically do not produce a noticeable color change when marked with infrared lasers. In such cases, adding laser marking additives can greatly enhance the material’s laser absorption ability, thereby achieving clear and durable marks.

Plastic laser marking additives can also meet the demand for high-contrast marking. Through chemical reactions or physical changes like foaming and carbonization, they can generate light marks on dark backgrounds or dark marks on light backgrounds. Furthermore, in some cost-sensitive applications, using laser marking additives can improve marking results without the need to replace equipment, thereby reducing production costs.

Complementary Optimization: Driving the Development of Plastic Laser Marking Technology Together

In the future, high-performance laser marking machines and plastic laser marking additives will exhibit a trend of complementary optimization. On the one hand, the technological progress of laser marking machines will continue to expand their application scope and marking performance. On the other hand, plastic laser marking additives will also be continuously improved to better meet the needs of specific materials and application scenarios.

Optimization Directions of Laser Marking Additives

The optimization of plastic laser marking additives mainly focuses on improving marking performance, reducing costs, enhancing environmental friendliness, and adapting to more materials and application scenarios. For example, adding specific nanomaterials such as zinc oxide nanowires and lanthanum oxide nanowires can significantly enhance the absorption and conversion efficiency of laser energy, thereby achieving clearer and more durable marks. Additionally, developing lead-free and volatile organic compound (VOC) – free marking additives will help improve their environmental performance.

Future Prospects of Collaborative Applications

The collaborative application of high-performance laser marking machines and plastic laser marking additives will bring more possibilities to the plastic marking industry. By working with laser marking machine manufacturers to develop marking additives suitable for specific laser parameters such as wavelength, power, and pulse frequency, the marking performance can be further enhanced. Moreover, the development of real-time monitoring and adjustment systems will enable marking additives to automatically adjust their formulas according to different marking requirements, achieving more flexible marking methods.

Conclusion

High-performance laser marking machines and plastic laser marking additives will complement each other in the future, rather than fully replacing one another. Technological advancements in laser marking machines will continue to enhance precision, efficiency, and eco-friendliness in plastic marking, while additives will play a critical role in optimizing marking quality, reducing costs, and meeting specialized needs. Their synergistic optimization will pave the way for broader applications of plastic laser marking technology, supporting the efficient, eco-friendly, and intelligent evolution of modern manufacturing.