Laser marking on plastic products is a critical process in industries like packaging, electronics, and automotive, where precision, durability, and aesthetics are paramount. Two popular technologies dominate this space: Fiber Laser Marking Machines and UV Laser Marking Machines. Each offers unique advantages depending on the material, application, and production requirements. This article compares their performance in plastic laser marking to help you choose the right solution for your needs.

Applicable Materials

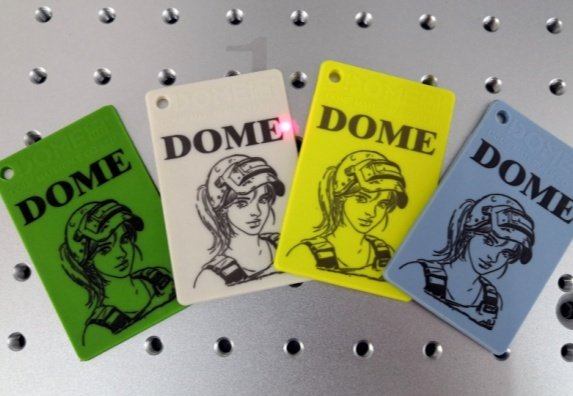

- Fiber Laser Marking: Excels on a wide range of plastics, including ABS, PC, PVC, PP, PA, TPU, and PE. It performs particularly well on harder plastics, delivering deep, high-contrast marks that stand out visually.

- UV Laser Marking: Ideal for heat-sensitive plastics like PET and PMMA. It’s perfect for soft or smooth plastics requiring high precision without compromising material integrity or causing deformation.

Marking Quality

- Fiber Laser Marking: Produces deep marks with excellent contrast, ensuring durability and wear resistance. This makes it suitable for applications where longevity and visibility are critical.

- UV Laser Marking: Offers superior beam quality for precise, smooth-edged marks with minimal heat impact. It prevents carbonization on plastic surfaces and enables unique effects like shallow embossing, making it ideal for high-quality, intricate designs.

Marking Speed

- Fiber Laser Marking: Known for faster marking speeds, fiber lasers are well-suited for large-scale or high-volume production environments where efficiency is key.

- UV Laser Marking: Typically slower, UV lasers are better for small-batch, high-precision tasks. However, advancements in UV laser technology are steadily improving their speed.

Equipment Cost and Maintenance

- Fiber Laser Marking: More cost-effective, with lower initial costs and maintenance expenses. Fiber laser components, such as the laser source, have a long lifespan, often up to 10 years.

- UV Laser Marking: Higher upfront costs due to expensive ultraviolet laser sources. Maintenance is also costlier, and the lifespan of core components is shorter compared to fiber lasers.

Flexibility

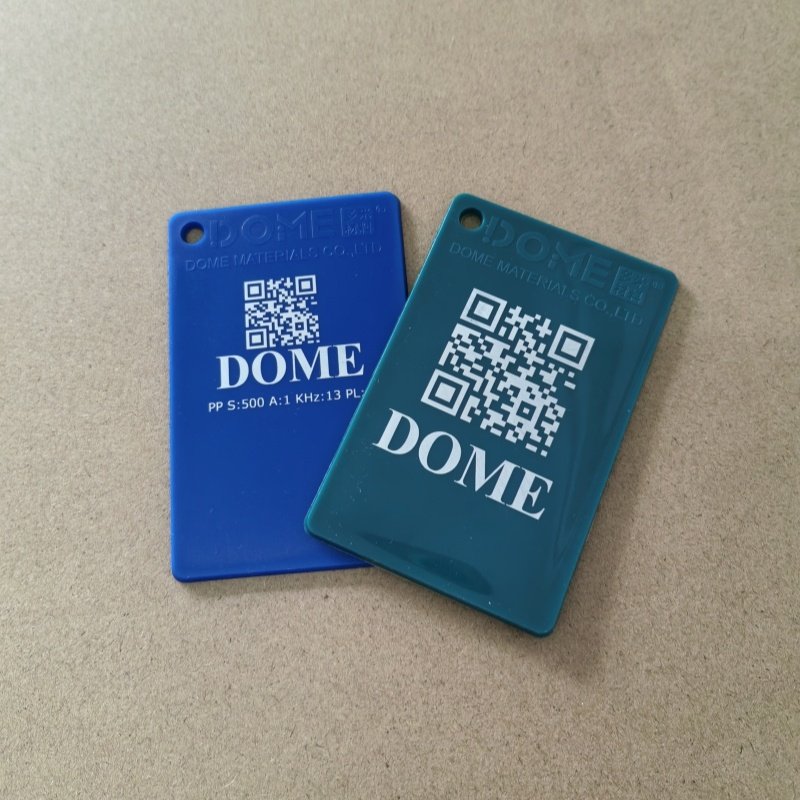

Both technologies offer high flexibility, allowing complex designs like patterns, text, serial numbers, and QR codes via computer software control.

- Fiber Laser Marking: Easily integrates with automated systems for online marking, making it versatile for industrial applications.

- UV Laser Marking: Shines in scenarios demanding precise positioning, delivering exceptional accuracy for intricate tasks.

Environmental Impact

- Fiber Laser Marking: Generates more heat, which may affect plastic properties or produce harmful gases during marking, requiring proper ventilation systems.

- UV Laser Marking: Uses a cold processing method, minimizing heat impact and eliminating harmful gas emissions, making it a more environmentally friendly option.

Choosing the Right Laser for Plastic Marking

Selecting the appropriate laser machine is crucial for achieving ideal marking colors in plastic laser marking applications. Below is a detailed comparison of fiber laser machines and UV laser machines, highlighting their suitability for different plastic marking needs:

Black Marking on Colored or White Polymers

Fiber laser machines easily produce high-contrast black marks on colored or white polymers by means of carbonization. In contrast, UV laser machines only deliver grayish marks that lack sharp contrast. Therefore, if high contrast black marking is a priority, fiber laser machines are the superior choice.

White Marking on Colored Polymers

UV laser machines excel at creating precise white marks on colored polymers. Unlike the carbonization effect of fiber lasers, UV lasers induce controlled chemical changes on the polymer surface, resulting in clear and bright white markings. Fiber lasers typically produce only gray or black marks on plastics without special additives, making them less suitable for white marking applications.

White Marking on Black Polymers

Both laser types offer options for white marking on black polymers. Fiber lasers use precise energy control to produce durable, scratch-resistant white marks, while UV lasers can also create white markings but with slightly less scratch resistance. For applications demanding long-lasting and scratch-proof marks, fiber laser machines are a better option.

Choosing the right laser machine based on your specific plastic marking requirements ensures optimal results and durability in your laser marking projects.

- Choose Fiber Laser Marking for cost-effective, high-speed marking on hard plastics like ABS or PVC, especially in high-volume production settings.

- Choose UV Laser Marking for heat-sensitive plastics like PET or applications requiring ultra-precise, high-quality marks with minimal environmental impact.

Enhancing Laser Marking on Plastics: Laser Marking Additives for Superior Quality

Optimizing laser marking solutions for plastics is crucial to achieve high-quality, efficient, and durable results. When working with fiber or UV lasers, certain plastics—such as polypropylene (PP), polyamide (PA), thermoplastic polyurethane (TPU), and polyethylene (PE)—tend to have low sensitivity to laser irradiation. In these cases, the addition of specialized laser marking additives becomes essential.

These additives enhance the material’s responsiveness to laser exposure, improving contrast and marking speed. As a result, they optimize the overall laser marking performance, delivering clearer, more durable marks on plastics that are typically challenging to process.

Conclusion

Both fiber and UV laser marking machines have distinct strengths for plastic marking. Fiber lasers offer speed, affordability, and durability for robust applications, while UV lasers provide precision and eco-friendly processing for delicate, high-quality needs. By understanding your material type, production goals, and budget, you can select the best laser technology to optimize your marking process.

Contact DOME Materials‘ expert today to find the perfect solution tailored to your specific needs and optimize your plastic laser marking performance.