In the world of plastics and polymers, TPU color masterbatch has emerged as a crucial component, offering a wide range of benefits and applications. From vibrant shoe soles to durable medical catheters, automotive interiors, and consumer electronics casings, TPU color masterbatch is the unsung hero behind the creation of colorful and high-performance TPU products. Acting as both a “color palette” and a “performance enhancer.” In this blog post, we will explore what TPU masterbatch is, its properties, processing characteristics, application areas, how to choose the right TPU masterbatch pellets, and the expertise of DOME Materials in manufacturing custom TPU masterbatch pellets.

What is TPU Color Masterbatch?

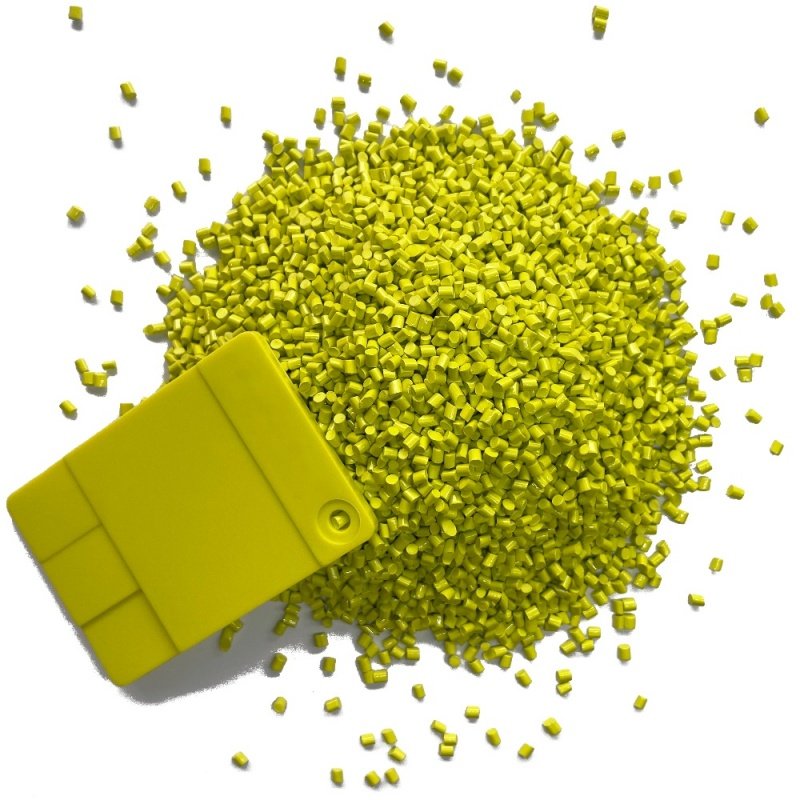

TPU color masterbatch consists of thermoplastic polyurethane (TPU) as the carrier resin, blended with high-concentration pigments or dyes and functional additives. Through compounding, extrusion, and pelletizing, it forms granular colorants. It is designed to efficiently color and enhance the properties of TPU during the manufacturing process.

By using TPU masterbatch, manufacturers can achieve consistent and vibrant colors in their TPU products while maintaining the integrity of the base material. Unlike generic masterbatches, TPU color masterbatches are fully compatible with TPU substrates, preserving elasticity, abrasion resistance, and low-temperature performance.

Five Key Features of TPU Color Masterbatch

- High Compatibility: Uses TPU as the carrier to prevent delamination or peeling, retaining over 90% of the base material’s tensile strength.

- Excellent Dispersion: Pigments with particle sizes ≤20 μm, pre-treated for uniform dispersion at 180–220°C, ensuring no crystal points or color variation.

- Heat and Migration Resistance: Stable up to 280°C, with UV resistance of Grade 7–8, maintaining color integrity for 3,000 hours outdoors.

- Preserved Mechanical Properties: At 3% addition, tear strength and abrasion loss vary by less than 5%.

- Eco-Friendly and Halogen-Free: Complies with REACH, RoHS, and FDA biocompatibility standards, suitable for medical-grade TPU.

Processing Characteristics of TPU Color Masterbatch

- Low Addition Rate: Optimal coverage at only 1–4%, reducing inventory and color-switching costs.

- Wide Processing Window: Compatible with injection molding, extrusion, blow molding, and calendering. Recommended processing: 180–220°C, screw L/D ≥ 24, back pressure 5–8 MPa for best dispersion.

- Easy Cleaning: Using an identical TPU carrier reduces color-switching time by over 30%.

- Drying Requirements: Dehumidify at 80°C for 2–3 hours to prevent moisture-induced bubbles.

Performance highlights of TPU Color Masterbatch

- Easy to Process: TPU masterbatch is designed for seamless integration into standard TPU processing methods (injection molding, extrusion, blow molding). It can be added directly to the TPU resin during melting, without requiring additional equipment or complex procedures.

- Low Melting Point: The TPU resin in the masterbatch has a relatively low melting point, enabling efficient processing at moderate temperatures. This saves energy and minimizes thermal degradation risk.

- Good Flowability: The molten masterbatch exhibits excellent flow, allowing it to fill molds and dies evenly. This yields components with precise shapes and dimensions and minimizes defects such as voids and surface irregularities.

Application Areas of TPU Masterbatch Across Industries

| Industry | Typical Products | Key Benefits |

| Footwear | Sneaker soles, air cushions | High elasticity, abrasion resistance, vibrant colors |

| Livestock Identification | TPU Ear Tags | UV-resistant, wear-resistant, high/low temperature-resistant, vibrant colors |

| Consumer Electronics | Phone cases, watch bands | UV resistance, sweat resistance, silky texture |

| Automotive | Interior skins, sealing strips | Scratch resistance, low VOC, and weather durability |

| Medical Devices | Catheters, sheaths | Biocompatibility, easy sterilization, and color coding |

| Industrial | Cable sheaths, conveyor belts | Flame-retardance, oil resistance, color coding |

How to Choose the Right TPU Color Masterbatch

Choosing the right TPU color masterbatch requires matching resin type, meeting quality standards, and ensuring consistent performance across your application. Consider resin polarity, certifications, processing needs, weather resistance, and batch control. Look for broad color options, strong dispersion and compatibility with your TPU grade, reliable supplier reputation, and cost efficiency.

- Match the Base Resin

- Polyester TPU vs. polyether TPU requires different formulations due to polarity differences.

- Certifications & Compliance

- Medical: FDA ISO 10993

- Automotive: IATF 16949

- Processing Requirements

- Thin films: require fine dispersion

- Thick injection-molded parts require high heat stability

- Weather & Light Resistance

- Outdoor use: UV Grade ≥ 7

- Accelerated aging: QUV 500 h with ΔE ≤ 1.5

- Batch Consistency & Quality Control

- Request SPC color reports with CPK ≥ 1.33

- Color Capabilities

- Seek a supplier offering a wide standard color range plus custom color matching

- Quality & Performance

- Assess color fastness, dispersion, and TPU compatibility

- Request samples and conduct tests to verify performance

- Supplier Reputation & Service

- Prefer suppliers with a proven track record, strong support, and reliable delivery

- Cost Considerations

- Aim for competitive pricing without compromising quality or performance

DOME Materials: Expert TPU Color Masterbatch since 2012

DOME Materials has specialized in custom TPU color masterbatch for over a decade, delivering high-quality solutions to clients worldwide. Our key advantages include:

- Extensive Expertise: Since 2012, we’ve served over 800 clients in the footwear, electronics, medical, and automotive industries.

- Rapid Customization: Prototypes ready in 24 hours from sample or color code receipt, with initial production batches delivered within 3 days.

- Precision Customization: Matches Pantone, RAL, Munsell, or physical samples with ΔE≤0.5; offers additives for antibacterial, antistatic, or flame-retardant properties.

- Professional Service: Our expert team provides tailored solutions, ensuring precise alignment with client specifications.

- Cost Efficiency: In-house twin-screw production and pigment pre-treatment lower wholesale prices by 10–20% without compromising quality.

- Trusted Reliability: Renowned for consistent quality and dependable delivery, we’re a proven partner for all TPU masterbatch needs.

Conclusion

TPU color masterbatch is a vital solution that seamlessly blends vibrant color, robust performance, and efficient processing. Selecting the right masterbatch ensures your products are both durable and visually striking. With over a decade of expertise, DOME Materials offers professional, rapid, and cost-effective customization, making us your trusted partner for high-quality TPU masterbatch solutions. For free samples or technical inquiries, contact sales@domematerials.com.