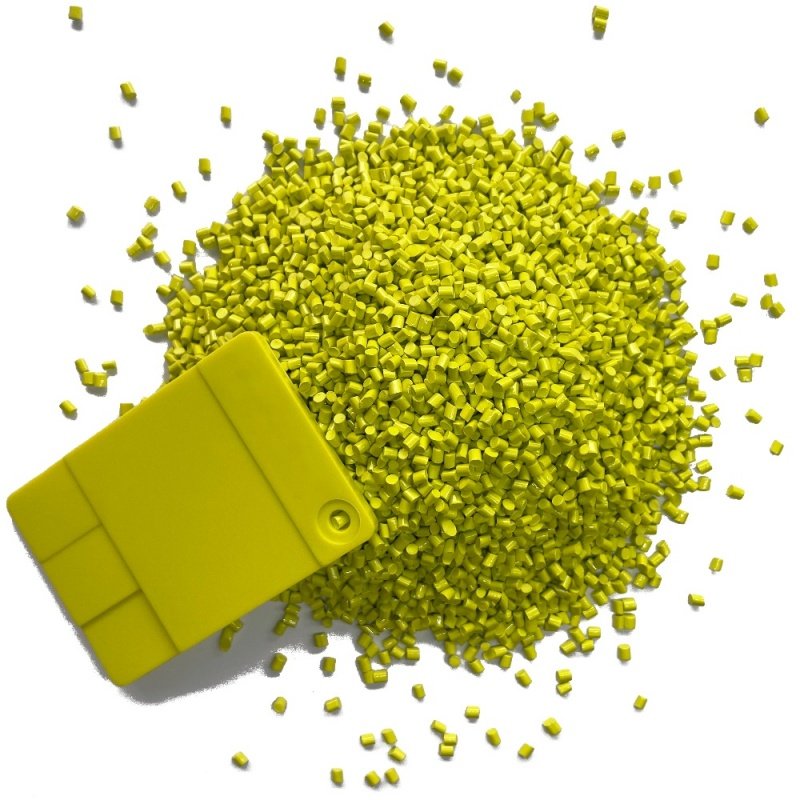

TPU Color Masterbatch Selection Guide: DOME Custom Coloring Solutions From Livestock Ear Tags to Medical Devices

As the product operation and marketing specialist at Shenzhen Dome Materials Co., LTD., I’ve witnessed firsthand how TPU (Thermoplastic Polyurethane) materials have become indispensable across