As a product expert at Shenzhen Dome Materials Co., LTD., I’ve seen how the right laser marking additive can boost plastic processing efficiency, while poor choices cause high scrap rates and delays. In modern manufacturing, laser marking is essential for traceability, branding, and compliance across industries like automotive, electronics, medical, and packaging. These laser-sensitive and laser-absorbing additives are vital for material suppliers. This guide covers the 5 core parameters every supplier should master to select and recommend the best additives.

Why Laser Marking Additives Matter in Plastic Processing

Laser marking additives enable precise, durable marks without ink—through reactions like carbonization, foaming, or color change. They improve marking speed, clarity, and reduce waste.

For instance, an automotive client cut scrap from 1.2% to 0.03% and boosted speed by 30% (saving $300,000+ yearly) by using our tailored laser-absorbing additive on ABS parts. Offering optimized additives helps suppliers stay competitive.

The 5 Core Parameters to Evaluate

Choose additives that match the plastic, laser system, and application. Here are the essentials:

1. Laser Type Compatibility: Fiber vs. UV Lasers

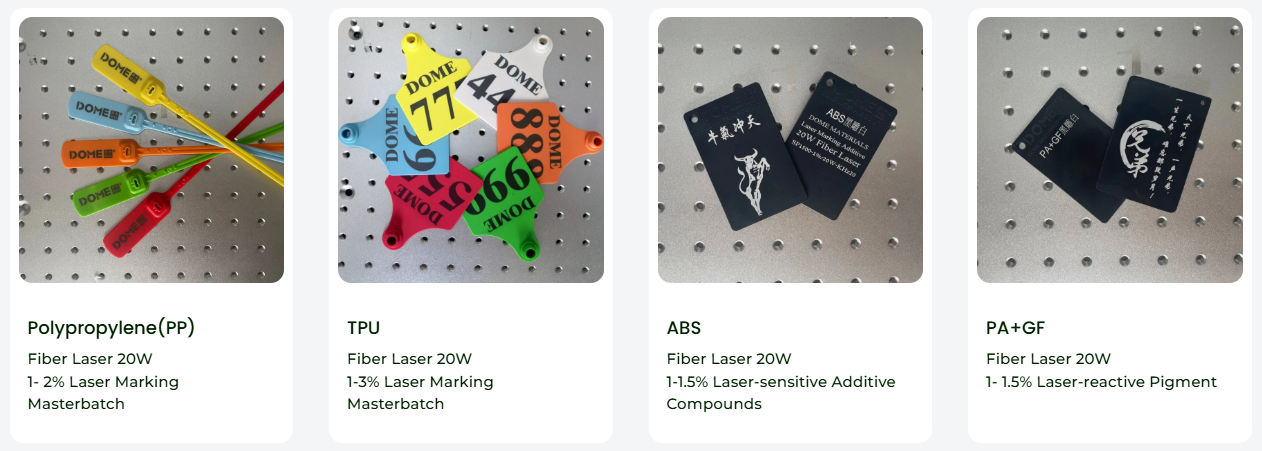

Match the additive to the laser wavelength for optimal results.

- Fiber Lasers (1064nm): Best for rigid plastics (ABS, PA, PC) in high-speed, deep marking. Additives absorb IR energy for sharp, heat-minimal marks—ideal for automotive and electronics.

- UV Lasers (355nm): “Cold” processing for heat-sensitive plastics (TPU, PE) and precision work (medical devices, packaging). Enables ultra-fine marks without surface damage, meeting FDA/GMP standards.

Mismatch (e.g., fiber additive with UV laser) causes faint marks.

2. Dosage: Finding the Cost-Performance Balance

Effective additives work at 1%-3% by weight.

- Low (1%-2%): Ideal for light/transparent plastics (clear PP, white ABS) and cost-focused applications.

- Higher (2%-3%+): For dark plastics or deeper contrast.

Avoid >5%—it raises costs and can reduce strength/flexibility. Always test starting low.

3. Carrier Compatibility: Matching Common Plastics

Additive chemistry must align with polymer properties:

- PP/PE: Non-polar; need high-dispersibility pellets to prevent clumping.

- ABS/PC: High-heat; requires stable additives (>300°C melting point).

- TPU/TPE: Flexible; use organic formulations to avoid brittleness.

- PA/PBT: Engineering grades; prioritize chemical resistance.

“Universal” additives often fail—tailor to the carrier.

4. Mark Contrast: Achieving Black, White, or Color Marks

Contrast ensures readability (e.g., QR codes, barcodes).

- Black Marks: Carbonization on light plastics (carbon-based additives).

- White Marks: Foaming/bleaching on dark plastics (TiO2 or rare-earth doped).

- Color Marks: Specialized (e.g., metal oxides for gold on PA).

High-resolution options support micro-text for medical use.

5. Environmental Resistance: Durability in Real Conditions

Marks must withstand temperature extremes (-40°C to 120°C+), humidity, and chemicals.

Choose heat/moisture-stable additives for outdoor/auto/marine applications. We’ve helped clients extend mark life from 6 months to 3+ years in high-humidity settings.

Common Mistakes and Real Failure Cases

- Fiber-optimized additive on UV laser → faint marks on TPU cases. Fixed with UV-specific formula.

- Overdosing (6%) dark PE → brittleness and uneven marks. Fixed at 3% with better dispersion.

DOME’s Advantage: Custom Laser Marking Additives

At DOME Materials, we create tailored formulations based on your specs: laser type, plastic, contrast needs, dosage, and environment.

We use premium materials, in-house testing, and provide samples. One medical client got FDA-compliant white marks on black TPU at 1.8% dosage—saving 20% vs. generics.

Quick Tips for New Suppliers

- Collect client details upfront (laser, plastic, color, environment).

- Test low dosage first.

- Check dispersion and mechanical impact.

- Partner with experts for support.

Conclusion: Get a Free Consultation from DOME

Mastering these 5 parameters—laser compatibility, dosage, carrier match, contrast, and resistance—ensures reliable, cost-effective solutions.

Shenzhen Dome Materials Co., LTD. offers free technical consultations to help you select or customize plastic laser marking additives. Contact us today for expert guidance on fiber/UV lasers, PP/PE/TPU/ABS, and more—let’s optimize your formulations!