In the world of plastics, achieving the perfect color and consistency is crucial for both aesthetics and functionality. This is where Color Masterbatch steps in as a game-changer. Color concentrate is a concentrated mixture of pigments and additives encapsulated during a heat process into a carrier resin. It is widely used in the plastics industry to impart color and specific properties to various plastic products. In this blog, we will delve into the intricacies of Color Masterbatch, its components, applications, and the nuances of selecting the right variant, particularly for TPU (Thermoplastic Polyurethane) applications.

What is Color Masterbatch?

Color Masterbatch is essentially a pre-made blend of colorants and other additives designed to be mixed with virgin polymers during the plastic manufacturing process. It is a cost-effective and efficient way to achieve consistent coloration and desired properties in plastic products. The primary function of pigment Masterbatch is to provide uniform color distribution throughout the plastic material while maintaining the integrity and performance of the end product.

Key Components of Color Masterbatch

Polymer colorant is composed of several essential components that work together to achieve the desired results:

- Pigments: These are the primary color-providing substances. They can be organic or inorganic and are chosen based on the desired color and application. For example, titanium dioxide is commonly used for white colors, while carbon black is used for black.

- Carrier Resin: This is the base material that holds the pigments and other additives together. The carrier resin should be compatible with the polymer being colored. Common carrier resins include polyethylene (PE), polypropylene (PP), and polystyrene (PS).

- Additives: These enhance the performance of the color Masterbatch. They can include UV stabilizers, antioxidants, flame retardants, and processing aids. Additives help improve the durability, stability, and processability of the final plastic product.

- Dispersing Agents: These are crucial for ensuring that the pigments are evenly distributed within the carrier resin. Proper dispersion prevents color inconsistencies and improves the overall quality of the plastic colorant.

Manufacturing Process of Color Masterbatch

Color Masterbatch is composed of several essential components that work together to achieve the desired results:

- Pigments: These are the primary color-providing substances. They can be organic or inorganic and are chosen based on the desired color and application. For example, titanium dioxide is commonly used for white colors, while carbon black is used for black.

- Carrier Resin: This is the base material that holds the pigments and other additives together. The carrier resin should be compatible with the polymer being colored. Common carrier resins include polyethylene (PE), polypropylene (PP), and polystyrene (PS).

- Additives: These enhance the performance of the coloring agent. They can include UV stabilizers, antioxidants, flame retardants, and processing aids. Additives help improve the durability, stability, and processability of the final plastic product.

- Dispersing Agents: These are crucial for ensuring that the pigments are evenly distributed within the carrier resin. Proper dispersion prevents color inconsistencies and improves the overall quality of the color compounds.

Manufacturing Process of Color Masterbatch

The production of Color Masterbatch involves several steps:

- Mixing: The pigments, carrier resin, and additives are blended in a high-intensity mixer. This ensures that all components are evenly distributed.

- Extrusion: The blended mixture is then fed into an extruder, where it is heated and melted. The extruder forces the molten material through a die, forming it into strands.

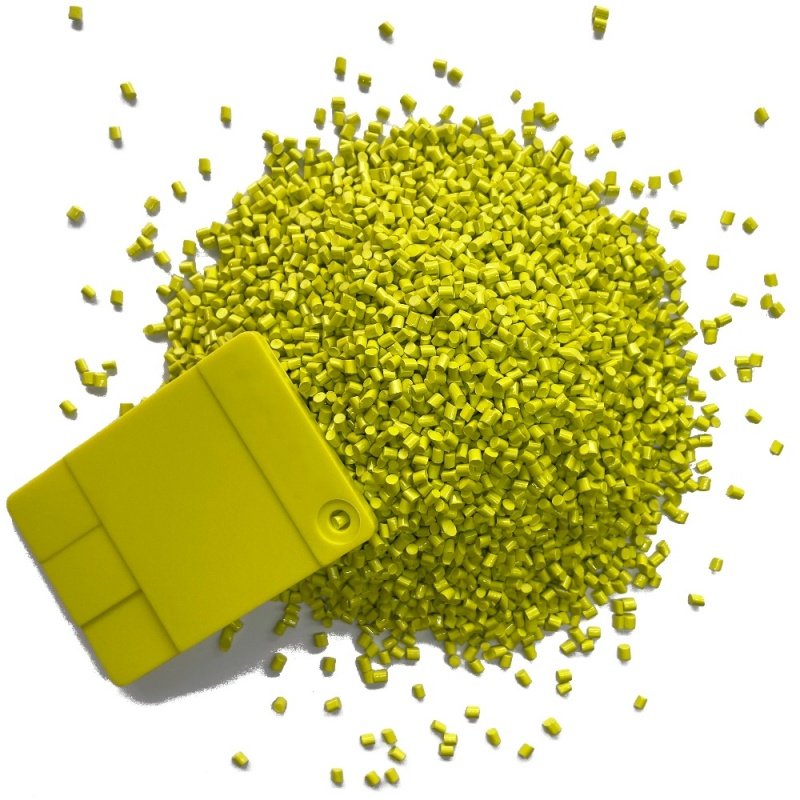

- Cooling and Pelletizing: The strands are cooled and cut into small pellets. These pellets are the final Dye Masterbatch product, ready to be mixed with virgin polymers during the plastic manufacturing process.

Applications of Color Masterbatch in the Plastics Industry

Color Masterbatch is incredibly versatile and finds applications in various sectors of the plastics industry:

- Packaging: It is used to color plastic bottles, containers, and films. Color Masterbatch ensures that packaging materials are visually appealing and meet branding requirements.

- Automotive: In the automotive industry, masterbatch pigment is used to produce colored plastic components such as dashboards, bumpers, and interior parts. It helps achieve consistent coloration and durability.

- Consumer Goods: Appliances, toys, and other consumer products benefit from Color . It allows manufacturers to create vibrant and aesthetically pleasing products.

- Construction: Color Masterbatch is used in the production of pipes, fittings, and other construction materials. It provides color consistency and enhances the appearance of these products.

TPU Dedicated Color Masterbatch: Special Considerations

TPU (Thermoplastic Polyurethane) is a unique material known for its flexibility, durability, and resistance to wear. When producing Color Masterbatch specifically for TPU, several factors need to be considered:

- Compatibility: The carrier resin in the color Masterbatch must be compatible with TPU. Incompatible resins can lead to poor dispersion and color inconsistencies.

- Heat Stability: TPU processing often involves high temperatures. The color Masterbatch used must be stable under these conditions to prevent degradation of the pigments and additives.

- Flexibility Retention: Since TPU is known for its flexibility, the color Masterbatch should not adversely affect this property. The additives and pigments used should be carefully selected to maintain the elasticity of the TPU.

- UV Resistance: TPU products are often used in outdoor applications. The color Masterbatch should contain UV stabilizers to prevent color fading and material degradation due to prolonged exposure to sunlight.

Choosing the Right Color Masterbatch

Selecting the appropriate Color Masterbatch is crucial for achieving the desired results in plastic manufacturing. Here are some tips to help you make the right choice:

- Understand Your Application: Consider the end-use of the plastic product. Factors such as temperature resistance, UV exposure, and mechanical properties should guide your selection.

- Check Compatibility: Ensure that the carrier resin in the color Masterbatch is compatible with the polymer you are using. Incompatibility can lead to poor color distribution and compromised product quality.

- Evaluate Color Consistency: High-quality Color Masterbatch should provide consistent coloration across batches. Request samples and perform tests to ensure uniformity.

- Consider Additives: Depending on your application, you may need specific additives such as UV stabilizers, flame retardants, or processing aids. Ensure that the Color Masterbatch contains the necessary additives for your requirements.

- Seek Expert Advice: Consult with the manufacturer or supplier of the color Masterbatch. They can provide valuable insights and recommendations based on your specific needs.

DOME Materials: A Leader in TPU Dedicated Color Masterbatch

When it comes to TPU-specific Color Masterbatch, DOME Materials stands out as a reliable and innovative provider. With years of experience in the plastics industry, DOME Materials specializes in producing high-quality Color Masterbatch tailored for TPU applications. Their products are designed to meet the unique challenges of TPU, ensuring compatibility, heat stability, and flexibility retention. By choosing DOME Materials, you can trust that you are getting a color concentrate that is optimized for your TPU manufacturing needs.

Conclusion

Color Masterbatch is an essential component in the plastics industry, providing a cost-effective and efficient way to achieve consistent coloration and enhanced properties in plastic products. Understanding its key components, manufacturing process, and applications is vital for making informed decisions. When it comes to TPU, selecting a dedicated Dye Masterbatch is crucial to maintain the unique properties of this versatile material. With the right Masterbatch compounds, manufacturers can produce high-quality, visually appealing, and durable plastic products that meet both functional and aesthetic requirements.