In today’s fast-paced manufacturing landscape, precision, durability, and traceability are non-negotiable. For industries relying on plastics, such as automotive, healthcare, electronics, and logistics, achieving permanent, high-contrast markings without compromising material integrity is a challenge. Enter DOME Materials’ laser-sensitive additives, also known as laser marking additives and laser-activated additives, which are game-changing solutions designed to elevate plastics laser marking across diverse applications. In this blog, we’ll explore how these additives work, their transformative impact across industries, and why they’re becoming the gold standard for engineers and manufacturers worldwide.

What are laser-sensitive additives?

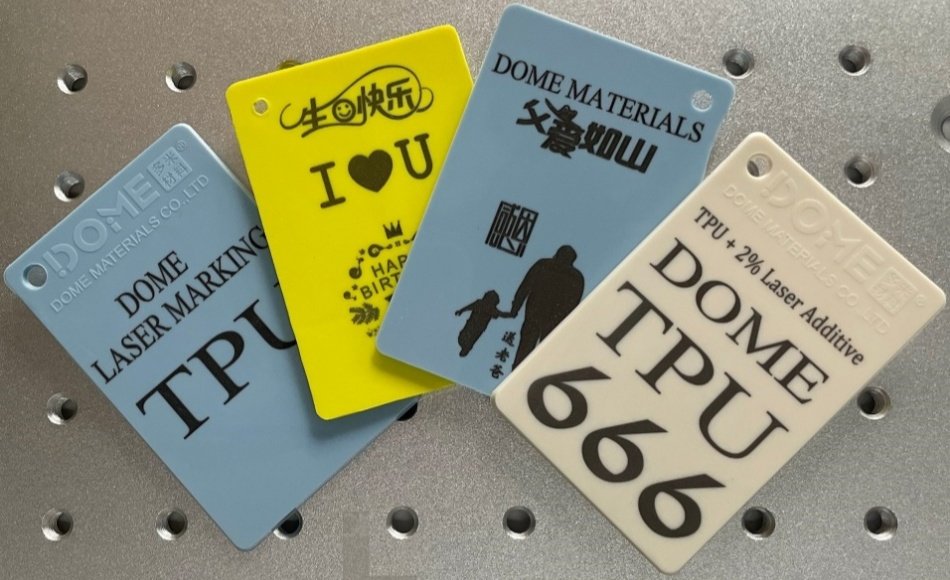

Laser-sensitive additives are specialized compounds blended into plastic resins to enhance laser responsiveness. Unlike traditional laser marking methods that struggle with certain plastics (e.g., polypropylene or TPU), DOME Materials’ additives absorb laser energy efficiently, creating sharp, legible marks without damaging the material. This ensures durable, high-resolution codes, logos, or serial numbers that resist abrasion, chemicals, and UV exposure.

By integrating these additives during the manufacturing process, companies eliminate the need for post-processing treatments or expensive material substitutions. The result? Seamless compatibility with existing laser systems and a streamlined workflow that saves time and costs.

Key Benefits of DOME Materials’ laser-sensitive additives

- Exceptional Clarity and Contrast: Even on challenging plastics, the additives produce deep black or vibrant marks with minimal heat input.

- Material Preservation: No melting, charring, or structural weakening—ideal for applications requiring dimensional stability.

- Broad Compatibility: Engineered for engineering plastics like PP, ABS, PA66, PC, and more.

- Sustainability: Reduces waste by enabling direct marking on raw materials, avoiding label adhesives or inks.

Now, let’s dive into how these advantages translate to real-world applications.

1. Industrial & Engineering Plastics: Reliability in Harsh Environments

From machinery components to construction materials, durability is paramount. DOME’s additives excel in marking:

- Safety labels: Permanent warnings or instructions on pipes, fittings, and machinery parts.

- Logistics tracking: Tamper-evident seals for e-commerce, livestock ear tags, and lead seals for construction.

- Plastic labels: High-contrast codes for asset tracking in warehouses or industrial settings.

Why it matters: Harsh conditions like moisture, UV radiation, or chemical exposure can degrade traditional markings. DOME’s additives ensure longevity, reducing maintenance costs.

2. Automotive Industry: Traceability Meets Aesthetics

Modern vehicles demand precision and brand consistency. Laser marking with DOME’s additives is used for:

- Dashboard components: Intricate logos or button engravings.

- Serial numbers: Traceability for recalls or quality control.

- Safety-critical parts: Tamper-proof identifiers on switches or connectors.

Industry edge: Compliance with regulations (e.g., EU’s Vehicle Identification Number standards) requires legible, permanent marks—DOME delivers both.

3. Electronics & Electrical: Security and Certification

Electronics demand pinpoint accuracy. Applications include:

- Circuit boards: Coding for warranty management or anti-counterfeiting.

- Housing: Branding for consumer-facing products like chargers or smart devices.

- Cables: Barcodes for inventory management.

Added value: Laser marks won’t crack under thermal cycling, ensuring reliability in high-stress environments.

4. Packaging: Compliance and Consumer Trust

In regulated sectors like pharmaceuticals or food, traceability is legally mandated. DOME’s additives enable:

- Batch codes: Tamper-evident markings on blister packs or vials.

- QR codes: Direct consumer engagement via product origins or recycling info.

- Expiry dates: Legible even after sterilization or autoclaving.

Consumer impact: Clear labeling builds trust, while compliance avoids legal penalties.

5. Medical Devices: Life-Saving Precision

In healthcare, errors are unacceptable. DOME’s additives support:

- UDI compliance: Unique Device Identification for surgical tools and implants.

- Serialization: Tracking disposable items like syringes or catheters.

- Sterilization resistance: Marks survive autoclaving without fading.

Critical advantage: Enhances patient safety and streamlines global supply chains.

6. Wire & Cable Industry: Anti-Counterfeiting in High-Stakes Applications

From aerospace to construction, fake wiring poses safety risks. Laser marking with DOME’s additives provides:

- Meter markings: Tamper-proof distance indicators.

- Insulation codes: High-contrast serial numbers for traceability.

Security benefit: Reduces counterfeiting, protecting brand reputation.

Why Choose DOME Materials?

While competitors focus on niche applications, DOME Materials’ additives are engineered for versatility. Whether marking flexible TPU for wearable tech or rigid PA66 for automotive parts, their solutions deliver unmatched consistency. Plus, they integrate seamlessly into existing production lines, minimizing downtime.

The Future of Plastics Laser Marking is Here

As industries prioritize sustainability, traceability, and efficiency, laser-sensitive additives are no longer optional—they’re essential. DOME Materials’ innovative formulas set a new benchmark, proving that even the toughest plastics can achieve flawless, permanent marks.

By adopting this technology, manufacturers gain a competitive edge: reduced costs, enhanced compliance, and happier customers. Ready to transform your marking process? Explore DOME Materials’ solutions today and unlock the full potential of plastics laser marking.

Interested in learning how DOME Materials’ laser-sensitive additives can elevate your operations? Contact our team for a consultation or download our product catalog to discover tailored solutions for your industry.

Keywords: laser-sensitive additives, plastics laser marking, DOME Materials, durable plastic markings, anti-counterfeiting solutions, industrial laser marking