Manufacturer in China

LASER MARKING ADDITIVE FOR PLASTIC

DOME Materials is a professional Laser Marking Additive manufacturer and wholesale supplier in China.

Check Out Our Selection of Laser Marking Masterbatches for Your Polymers.

- Free Samples

- Fast Delivery

- Customizable

- Competitive Price

Product Model: DM-GW0032 / DM-GW32s /DM-GW0042 / DM-GW0052 / DM-GW0062

Laser marking is a cutting-edge, versatile technology that delivers durable and precise marks on plastic surfaces, making it a superior choice compared to traditional marking methods. Ideal for both high-volume production and smaller batch sizes, this method ensures abrasion-resistant marks on a wide range of materials, including soft, hard, and even non-flat surfaces. While different polymers vary in their reaction to laser marking, the use of laser marking additives can help achieve optimal results. These additives are non-toxic, eco-friendly, and maintain the original color of plastics, elastomers, and rubbers. Laser marking technology also enables exceptionally precise markings, including photo-quality designs, making it a reliable, long-term solution for barcodes, lot numbers, and intricate decorative patterns.

Take Your Business To The Next Level

With our cutting-edge laser marking additives, you can now create high-quality, permanent marks on all types of plastic materials from polypropylene to thermoplastic Polyurethane with ease and precision.

Our additive is easy to use and integrates seamlessly into your existing production process, ensuring minimal disruption to your operations. Plus, it’s environmentally friendly, making it a safe and sustainable choice for your business.

With Laser Marking Additive for Plastic, you’ll enjoy faster throughput, improved product quality, and a wider range of design options to differentiate your products.

Choose DOME’s Laser-sensitive Additive and take your products to the next level. Contact us today to learn more and see the difference for yourself!

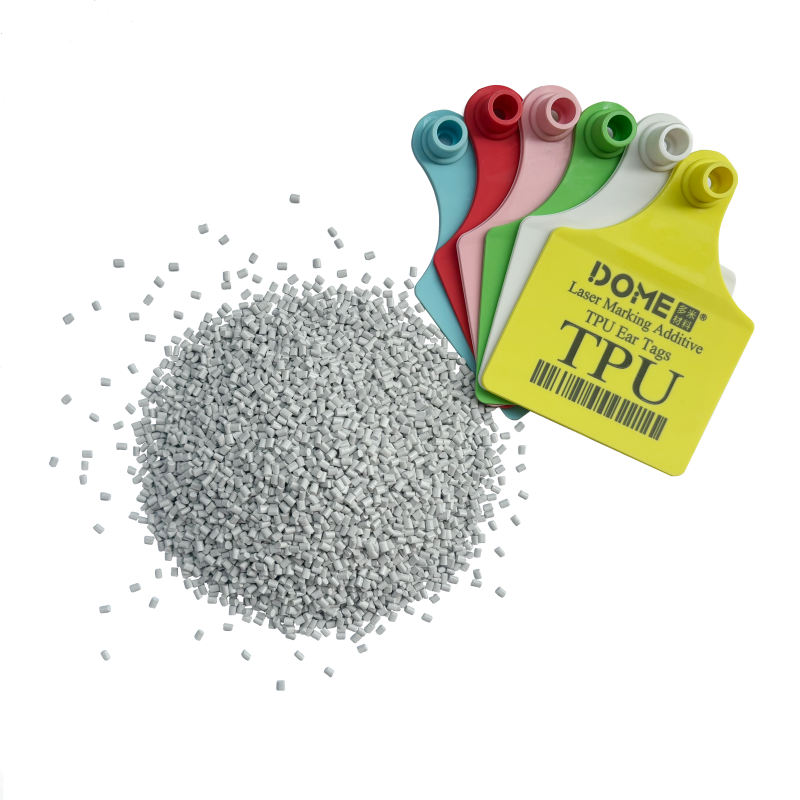

Application - Laser-marked Black On Colored Polymer

Plastic laser marking additives are increasingly popular in a variety of industries, as they create a black mark on white or colored plastics that makes printed information easier to read.

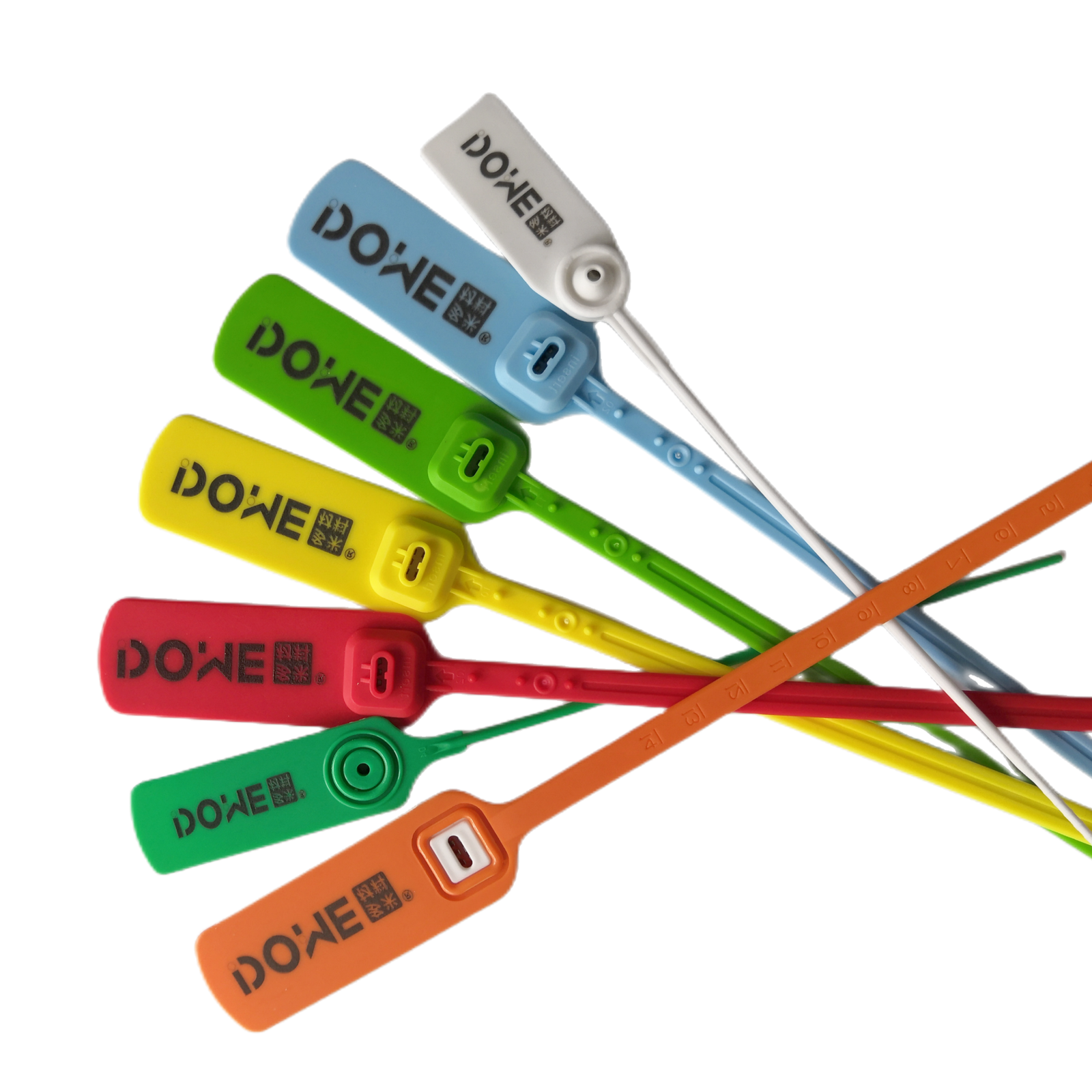

DOME Laser Marking Masterbatches are widely used for a range of applications, including livestock ear tags, security seals, electronic products, food and household packaging, home appliances, medical and automobile products, as well as buttons for keyboards and remote controllers.

DOME™ Laser Marking Additives

Top-Picks In Stock: Laser Marking Additives for Black Laser Marking on White/Colored Plastics

| Product Name | Laser Marking Additives for Black Laser Marking on White/Colored Plastics | |||||

| Model No. | DM-GW0032S | DM-GW0042 | DM-GW0052 | DM-GW0062 | DM-GW0082S | DM-GW0092 |

| Dosage | 1%-3% | 1%-3% | 1%-3% | 1%-3% | 1%-3% | 1%-3% |

| Laser Type | Fiber Laser | Fiber Laser | Fiber Laser | UV Laser | Fiber Laser | Fiber Laser |

| Whether Contains Antimony | YES | YES | YES | NO | YES | NO |

| Resin Compatibility | Universal for PP / PE / TPU / PC / PA / PET / PBT / POM / TPE / TPV / ABS / SEBS / PVC |

|||||

| Color | Ash White | Gray White | Gray | Whitish | Gray | Gray |

| Appearance | Pellet 2.5-3.0mm | Pellet 5-6mm | Pellet 2.5-3.0mm | Pellet 2.5-3.0mm | Pellet 2.5-3.0mm | Pellet 2.5-3.0mm |

| Processing Temperature | >180 °C | |||||

| Baking Temperature | <90 °C | |||||

| Melt Flowing Rate | 10.0-25.0 (g/10min. 190℃, 5KG) | |||||

| Density(g/cm³) | 1.2-1.8g/cm³ | |||||

| Bulk Density(g/cm³) | 90-110g/100ml | |||||

| Heat Stability | Stable up to 280 °C | |||||

| PH Value | 7-11 | |||||

| Certification | ISO9001 MSDS | |||||

| Packing Details | 25KGs/Carton, Carton Size: 500*380*160mm | |||||

| HS No. | 3824999999 | |||||

| Place of Origin | Shenzhen China | |||||

| Classification | Chemical Auxiliary Agent | |||||

| Brand Name | DOME™ | |||||

Laser Marking Masterbatch - Black Laser Mark on Colored Polymer

Wholesale at Competitive Prices

Don’t miss out and take advantage of our factory prices. Check out our catalog and see only the best deals for you and your Polymer laser marking needs. On top of our competitive prices, enjoy huge discounts for bulk orders as well.

In our well-maintained raw material warehouse spanning 1000 square meters, we maintain a consistent and reliable inventory of raw materials. This enables us to minimize the expenses associated with raw material procurement. As the foremost manufacturer of laser marking additives in China, we offer a comprehensive one-stop service. Typically, orders weighing up to 5 tons are swiftly delivered within 1-3 working days, effectively reducing procurement costs and enhancing operational efficiency for our valued customers.

Features and Benefits of Laser Marking for Plastic

- Non-contact processing, durability;

- High precision, fast, high legibility, reliability;

- Forming a top-quality micro mark;

- Environment-friendly;

- Easy to use, strong security features;

- Strong traceability of products;

- High-speed automatic processing can be achieved ;

- The overall production cost of individual parts is far less than that of printing traditional inks.

Black Mark on Color Polymer

White Mark on Black Polymer

White Mark on Color Polymer

Black Mark on Transparent Polymer

White Mark on black Products – Laser Marking Powder

Black Mark on Color Products – Laser Marking Powder

Customized Laser Marking Additives & Custom Modified Compounds

Our laser marking aids are suitable for a variety of plastic materials, such as PE / PP / PC / TPU / ABS / PC+ABS / PBT / HIPS, etc.

We can also provide custom-modified masterbatches upon request. You have the choice between purely laser additive masterbatches or combination masterbatches, consisting of carrier polymer, additives, and the color of your choice. such as modified ABS materials for the ABS keyboard (70% ABS Resin + 30% PMMA +4% Laser Marking Masterbatch), custom modified TPU materials for livestock ear tags (TPU Resin + Laser Marking Additive + Pigment), and modified materials for cables, etc.

We do not require a minimum order quantity for the laser marking additives, so you can buy according to the actual needs of your project, no need to make an additional inventory.

Package and Storage

- Caton Size: 500*380*160mm | 420*380*160mm

- Weight: 25Kgs/carton | 20Kgs/carton

- Laser additive is packaged in a plastic box or a carton lined with a PE bag;

- Laser additive is non-dangerous goods;

- Please store in dry and ventilated conditions;

- Waterproof and moisture-proof;

- Avoid sun exposure;

- Please seal the unused portion of the Laser additive;

- Please use it up within 24 months.

- DELIVERY: 1-3 working days under 5000Kgs, 5-7 working days for Biger Order

Frequently Asked Questions

This section contains a few FAQs that our customers ask. If your question is not here, contact us today, and we will answer directly.

Can plastic laser marking additives be combined with other additives for better performance?

Plastic laser marking additives can work synergistically with other additives to optimize plastic performance. By combining various additives, manufacturers can tailor laser marking properties, achieving benefits such as enhanced contrast, improved durability, or specific color effects. For instance, pairing laser marking additives with UV stabilizers enhances resistance to sunlight-induced fading, ensuring long-lasting results. Moreover, integrating additives like impact modifiers or flame retardants with laser marking solutions further boosts the plastic materials’ overall strength, safety, and versatility. This flexibility makes laser marking additives an essential choice for creating durable and customized plastic products.

Will adding laser marking additives affect the original color matching of plastic products?

Because the amount of our laser marking additives is very small, usually within 3%, it will basically not affect the color matching of the product.

How do different plastic laser marking additives impact the laser marking contrast and readability of plastic materials?

Different plastic laser marking additives can have a significant impact on the laser marking contrast and readability of plastic materials.

It’s important to note that the impact of these additives on laser marking contrast and readability can vary based on factors such as additive concentration, laser parameters, and the type of plastic being marked. Conducting tests and optimizing the laser marking process for a specific combination of plastic and additive is usually necessary to achieve the desired results.

Will the more laser additives added to the plastic, the better the laser marking?

It is not that the more plastic additives are added, the better the marking effect will be. When laser marking white on black plastic, we generally recommend adding 1%-2% of plastic additives, usually not higher than 2%, adding more will affect the laser marking effect. For different plastic products, the amount of laser additives used will vary. For specific standards, please refer to the professional guidance of DOME™.

Request A Laser Marking Masterbatch Quote for Your Project - Laser Black Mark on Colored Polymers

Get an instant quote or let us know what you’re looking for and we’ll get back to you soon!