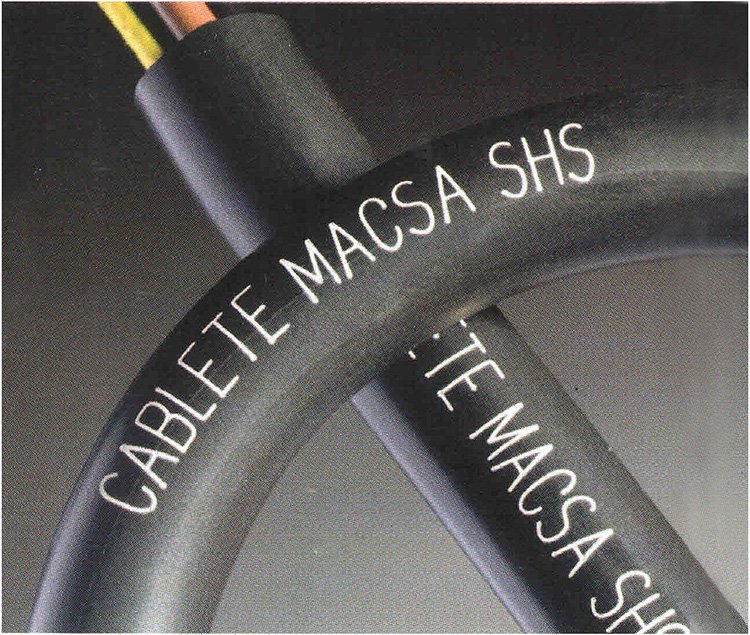

Laser marking plays a significant role in the wire and cable industry. It provides reliable, durable, and easy-to-read markings without the need for consumables, and at a low cost. Laser marking also requires the selection of appropriate laser marking additives to achieve excellent marking performance, especially in high-speed production environments.

Permanent Marking Solutions for Wire and Cable Manufacturers: Meeting the Demands of Complex Designs and Logistics.

Wire and cable manufacturers are increasingly required to mark their products permanently. This permanent mark can facilitate installation and repairs, as well as streamline logistics. With the rise in data and voice traffic leading to more complex cables and designs, manufacturers have a variety of marking technologies to choose from, including embossing wheels, ring marking, engraving, offset printing, length stamping, hot foil printing, laser marking, and inkjet marking. Regardless of the method chosen, it must be reliable, highly durable, and produce a clear mark over the entire cable length.

Advantages of Laser Marking in Plastic Manufacturing: Permanent and Efficient Component Marking

Laser marking is a well-established technology in the plastics manufacturing industry for marking components. Due to the ease of changing layouts, and the permanence of the inscription, laser marking has become a logical choice for printing plastic parts. The process creates an indelible differentiated marking useful for long-term identification and has minimal effect on product integrity. Machinery developments support faster production.

Advancements in Laser Marking Technology: Overcoming Speed and Logistical Challenges

The technology has had a significant negative impact on extrusion speed, which has been the primary downside. Additionally, certain manufacturing processes have required a 2-step laser marking process, creating logistical challenges in production. However, recent advancements by top laser marking equipment manufacturers have made high-speed “on the fly” marking possible with fiber laser technology, reaching speeds of up to 400m/min. DOME Materials works closely with these manufacturers and can assist our customers in finding the right equipment.

Laser marking remains readable for many years. Unlike other marking methods, it does not need consumables like hot foil tapes, inks, and solvents. The cost of maintaining a laser marking system is also lower than that of another printing system.

Features and Advantages of Laser Marking

Features:

- High precision and accuracy: Laser marking offers high levels of precision and accuracy, allowing for intricate and detailed markings on various materials.

- Non-contact process: Laser marking is a non-contact process, meaning there is no physical contact between the laser and the material being marked, reducing the risk of damage to the material.

- Permanent and durable markings: Laser markings are permanent and resistant to wear, making them ideal for industrial and commercial applications.

- Versatility: Laser marking can be used on a wide range of materials, including metals, plastics, glass, and ceramics.

- Fast and efficient: Laser marking is a fast and efficient process, allowing for high-speed marking of products and components.

Advantages:

- Improved traceability: Laser marking allows for the easy and accurate tracking of products and components, enhancing traceability in manufacturing and supply chain processes.

- Customization: Laser marking enables the customization of products with logos, serial numbers, barcodes, and other identifying marks.

- Reduced operational costs: Laser marking can lead to cost savings by eliminating the need for consumables such as inks or dyes, and reducing maintenance and downtime associated with traditional marking methods.

- Environmentally friendly: Laser marking is a clean and environmentally friendly process, as it does not produce any waste or emissions.

- Compliance with industry standards: Laser marking can help companies comply with industry standards and regulations for product identification and traceability.

Laser Marking Additives: Enhancing Cable Production and Sustainability

Laser marking additives have become an essential component in the cable production industry. These additives are used to enhance the visibility and durability of markings on cables, ensuring that important information such as serial numbers, manufacturer details, and specifications remain legible throughout the cable’s lifespan.

The use of laser marking additives allows for precise and permanent marking on a variety of cable materials, including PE, TPU, PVC, TPE, TPR, etc. This ensures that cables can be easily identified and traced, which is crucial for quality control and maintenance purposes.

Furthermore, the application of laser marking additives in cable production also contributes to environmental sustainability. By eliminating the need for traditional ink-based marking methods, these additives reduce waste and minimize the use of harmful chemicals.

In conclusion, the implementation of laser marking additives in cable production is a testament to the industry’s commitment to innovation and quality. These additives not only improve the functionality and longevity of cables but also align with the growing demand for sustainable manufacturing practices.

Enhancing Cable Jacket Marking with Laser Marking Additives: Achieving High-Quality Results

Depending on the polymer chosen for the cable jacket and its color, certain lasers may lightly mark the plastic or leave an indentation mark. Adding laser-sensitive additives to the thermoplastic jacketing creates a great marking contrast and high-quality line edge detail, even at high extrusion line speeds. As the laser beam is used during processing, it activates the laser-sensitive additives, changing their molecular structure and causing a color change that enhances laser marking contrast.

Optimizing Laser Marking in Cable Manufacturing: The Importance of Additive Expertise and Color Design

Effective laser marking requires expertise in pigments, additives in a cable compound, and the type of resin used for the cable jacket. Threshold concentration limits and color design must also be considered. It is important to emphasize that marking and contrast can be optimized for each color and polymer. No universal solution exists; the selection of the appropriate laser marking additive is critical to achieving excellent marking performance.

Ensuring Regulatory Compliance and Quality in Laser Formulations for Cable Marking

Laser formulations should not negatively impact a cable’s look or its mechanical, physical, or functional qualities. The additive chosen must adhere to the European Union’s Restriction of Hazardous Substances (RoHS) directive and meet other regulatory standards. Therefore, despite significant improvements in the laser marking process, a high level of skill is still necessary for successful implementation.

Maximizing Laser Marking Success with Expert Color and Additives Suppliers

Success hinges on collaborating with a skilled color and additives supplier to assist with a manufacturer’s laser marking process. Based on our experience, utilizing a “smart” concentrate that includes the laser marking additive along with necessary colorants and additives, frequently quickly compensates for the additional material additive expenses, while also delivering exceptional marking contrast at high output rates.

DOME Materials’ Laser Marking Additives: A Versatile Solution for Cable Marking

DOME Materials’ laser marking additives offer a versatile solution for marking a variety of cable materials, including PE, PVC, TPU, TPE, and TPR. These additives can produce black markings on white or colored cables, as well as white markings on black cables. This flexibility allows for seamless integration into a wide range of cable manufacturing processes, ensuring high-quality and durable markings. With DOME Materials’ laser marking additives, cable manufacturers can achieve consistent and precise markings on their products, meeting the demands of their customers and industry standards.

The addition of carbon black in black cables can have a significant impact on the laser marking effect.

It is important to consider that DOME’s laser marking additives have the capability to directly substitute carbon black or black masterbatch/black powder in black cables. This eliminates the need for additional carbon black or black pigments, which can potentially affect the laser marking effect. Therefore, it is crucial to carefully consider the use of DOME’s laser marking additives to ensure the desired laser marking effect is achieved without any adverse impact from the presence of carbon black.

DOME Materials’ Laser Marking Additives: The Ideal Choice for Cable Marking

These laser marking additives are specifically designed to provide high-quality, durable markings on a variety of cable materials. With their advanced technology, DOME Materials’ Laser Marking Additives offer precise and consistent markings, ensuring clear and legible identification for cables in various applications.

The use of laser marking additives provides numerous benefits for cable manufacturers. These additives are compatible with a wide range of cable materials, including PVC, PE, and XLPE, making them a versatile solution for marking cables in different industries. Additionally, DOME Materials’ Laser Marking Additives are formulated to withstand harsh environmental conditions, ensuring that the markings remain intact and readable throughout the cable’s lifespan.

Furthermore, the laser marking process offers a non-contact and non-destructive method of marking cables, eliminating the risk of damaging the cable’s insulation or structure. This results in a cost-effective and efficient marking solution for cable manufacturers, as it reduces the need for additional processing steps and minimizes the risk of product defects.

In conclusion, DOME Materials’ Laser Marking Additives are the ideal choice for cable marking, offering a reliable and efficient solution for cable manufacturers. With their compatibility with various cable materials and their ability to withstand harsh conditions, these additives provide clear and durable markings that meet the industry’s stringent requirements. By choosing DOME Materials’ Laser Marking Additives, cable manufacturers can ensure the quality and reliability of their products while optimizing their production processes.

Laser marking additive selection is crucial for success.

DOME Materials’ expertise in specialty polymer materials, colors, and additive formulations, combined with its experience in the cable industry and close relationships with industry participants, gives you confidence in successfully implementing laser marking in your production facilities. For more information about DOME™ laser marking solutions, please visit www.domematerials.com or contact us at sales@domematerials.com