Some Knowledge Points About ABS Materials

ABS is a polymer formed by the copolymerization of three monomers of acrylonitrile (23-41%), butadiene (10-30%), and styrene (29-60%). The English name is Acrylonitrile-Butadiene-Styrene, referred to as ABS. ABS has the unique advantages of toughness, rigidity, and hardness. It develops rapidly and is widely used.

ABS Plastic: Characteristics, Properties, and Applications

What is ABS Plastic?

ABS (Acrylonitrile Butadiene Styrene) is an amorphous, opaque thermoplastic engineering plastic, typically available as light yellow pellets or beads. Renowned for its toughness, rigidity, and excellent balance of properties, ABS is a go-to material for a wide range of applications, from automotive parts to consumer electronics.

Core Keywords: ABS Plastic, Acrylonitrile Butadiene Styrene, Thermoplastic Properties

Key Characteristics of ABS Plastic

ABS derives its superior properties from its three constituent monomers: acrylonitrile, butadiene, and styrene. Each contributes unique attributes to the material:

- Acrylonitrile: Provides chemical corrosion resistance, oil resistance, and enhanced rigidity and hardness.

- Butadiene: Improves toughness, impact resistance, and cold resistance, making ABS durable under stress.

- Styrene: Enhances dielectric properties, surface gloss, and processing fluidity for smooth manufacturing.

SEO Tip: Optimize for long-tail keywords like “ABS plastic properties” and “acrylonitrile butadiene styrene benefits.”

Physical and Chemical Properties

- Appearance and Form: Light yellow, opaque pellets or beads with a non-toxic, odorless profile.

- Thermal Properties: Melting temperature ranges from 217–237°C, with thermal decomposition above 250°C.

- Dimensional Stability: Low molding shrinkage ensures excellent dimensional accuracy.

- Low Water Absorption: Suitable for applications requiring moisture resistance.

- Surface Versatility: Easily decorated through painting, dyeing, or electroplating for enhanced aesthetics.

Processing Advantages of ABS

ABS is highly processable, making it a favorite in manufacturing:

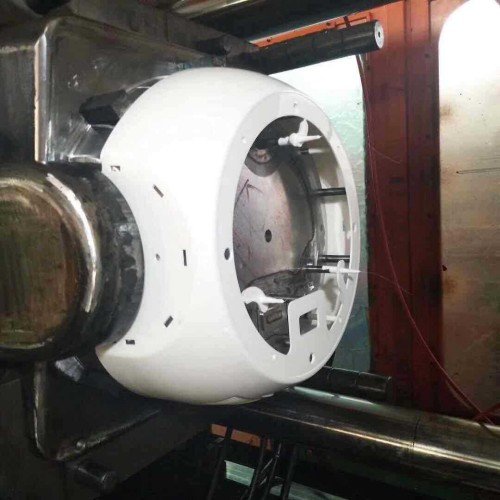

- Versatile Processing: Supports injection molding, extrusion, calendaring, and thermoforming.

- Secondary Processing: Exceptional for machining, welding, bonding, painting, and electroplating. ABS surfaces exhibit superior adhesion to metal coatings, offering 10–100 times stronger bonding than other plastics, improving both aesthetics and weather resistance.

- Specialized Techniques:

- Welding: Uses flame-retardant ABS electrodes for strong joins.

- Bonding: Achieved with a 10% ABS solution in methyl ethyl ketone.

- Forming: Hot oil or hot air for pipe shaping; vacuum forming for extruded or calendered sheets.

- Cold Forming: Recent advancements enable cold-stamping for large automotive parts, rivaling steel and aluminum.

SEO Tip: Target keywords like “ABS plastic processing” and “ABS cold forming applications.”

Limitations of ABS Plastic

Despite its strengths, ABS has some drawbacks:

- Poor Weather Resistance: Butadiene’s double bonds lead to aging, discoloration, or cracking under prolonged outdoor exposure, reducing impact strength and toughness.

- Solubility: Easily dissolves in aldehydes, ketones, esters, and chlorinated hydrocarbons.

- Flammability: Burns slowly with yellow flames and black smoke, emitting a distinct odor without molten dripping.

- Low Heat Distortion Temperature: Limits use in high-temperature environments.

Combustion Characteristics

ABS burns slowly and continues to combust after removal from a flame, producing yellow flames and black smoke. It softens during burning, emits a unique odor, and does not drip molten material, which can influence its application in fire-sensitive environments.

Applications of ABS Plastic

Thanks to its robust properties, ABS is widely used in:

- Automotive: Large components like dashboards and bumpers are made due to cold-forming capabilities.

- Electronics: Housings for phones, keyboards, and appliances for durability and aesthetics.

- Consumer Goods: Toys, luggage, and household items for impact resistance and glossy finish.

- Industrial: Pipes, fittings, and machinery components for chemical resistance and rigidity.

Material properties of ABS

1. Conventional performance:

Plastic ABS is non-toxic and tasteless; its appearance is ivory, translucent, or transparent granules or powder. The density is 1.05~1.18g/㎝3, the shrinkage rate is 0.4%~0.9%, the elastic modulus is 2 GPa, the Poisson’s ratio is 0.394, the hygroscopicity is <1%, the melting temperature is 217~237℃, and the thermal decomposition temperature is >250 ℃.

2. Mechanical properties:

Plastic ABS exhibits excellent mechanical properties, with outstanding impact strength and the ability to withstand extremely low temperatures. It also demonstrates exceptional wear resistance, good dimensional stability, and resistance to oil. As a result, it is suitable for applications involving medium loads and low-speed bearings. The creep resistance of ABS is larger than that of PSF and PC, but smaller than that of PA and POM.

3. Thermal properties:

Plastic ABS has a thermal deformation temperature ranging from 93°C to 118°C, and annealing can increase the product’s temperature resistance by approximately 10°C. ABS exhibits a certain level of toughness even at -40°C, allowing it to be utilized within a temperature range of -40°C to 100°C.

4. Electrical properties:

Plastic ABS has good electrical insulation and is hardly affected by temperature, humidity, and frequency, so it can be used in most environments.

5. Environmental performance:

Plastic ABS is not affected by water, inorganic salts, alkalis, and various acids, but it is soluble in ketones, aldehydes, and chlorinated hydrocarbons. It will cause stress cracking when it is eroded by glacial acetic acid and vegetable oil. The weather resistance of ABS is poor, and it is easy to degrade under the action of ultraviolet light; after half a year outdoors, the impact strength drops by half.

ABS injection mold process conditions:

Drying treatment: ABS material is hygroscopic and requires drying treatment before processing. The recommended drying condition is at least 2 hours at 80-90°C. Material humidity should be guaranteed to be less than 0.1%.

Melting temperature: 210~280℃; recommended temperature: 245℃.

Mold temperature: 25~70℃. (Mold temperature will affect the finish of plastic parts; a lower temperature will result in a lower finish.)

Injection pressure: 500~1000 bar.

Injection speed: medium to high speed.

Application of ABS materials

Electrical field:

The casing and internal components of refrigerators, televisions, washing machines, air conditioners, telephones, air conditioners, and other electrical appliances.

Automotive field:

Automotive dashboards, body panels, interior trim panels, steering wheels, sound insulation panels, door locks, bumpers, ventilation ducts, and many other components. ABS is mainly used for impact resistance, such as strength, stiffness, and formability. Accessories include fenders, armrests, vent covers, supports, cushion extensions, and more.

Building materials field:

ABS pipes, ABS sanitary ware, and ABS decorative boards. In addition, ABS is also widely used in packaging, furniture, sporting goods and entertainment products, machinery, and instruments in industry.

Office equipment:

Taking advantage of the excellent impact resistance, excellent rigidity, dimensional stability, and formability of ABS board, it is economical and practical to manufacture various office equipment shells. Office equipment such as fax machines, copiers, typewriters, and computer monitors, keyboards, etc., has higher requirements for fire protection, so generally, flame-retardant ABS is used in the preferred order.

Mechanical field:

ABS plastic casing can be used in the production of mechanical equipment and general mechanical parts, such as water tanks, exterior shells, electrical cabinets, battery tanks, gear bearings, pump impeller mold models and fasteners, bolts, and cover plates.

Mold model:

Due to its superior processing performance, light specific gravity, and low price, ABS plastic has been widely used to manufacture mold models for household appliances, automobiles, mechanical equipment, and testing instruments in recent years. Currently, the world’s leading three-dimensional prototype is made of ABS as standard material, then you can make any appearance, suitability, and related function models of any new product you want to test. It has the best performance-price ratio among similar products.

Future Outlook for ABS Plastic

With ongoing innovations in ABS formulations, such as enhanced flame-retardant and weather-resistant variants, the material continues to evolve. Its adaptability to cold-forming processes and strong electroplating adhesion make it a sustainable choice for modern manufacturing, particularly in the automotive and electronics industries.

Trend Insight: The global ABS market is projected to grow steadily, driven by demand in automotive, electronics, and consumer goods, with a focus on eco-friendly and high-performance grades.

Conclusion: Why Choose ABS Plastic?

ABS plastic stands out for its toughness, versatility, and ease of processing, making it ideal for diverse applications. While it has limitations like poor weather resistance, its strengths in dimensional stability, chemical resistance, and aesthetic adaptability make it a cornerstone of modern manufacturing.

Others:

ABS can be used to make structural foam plastics, flame-retardant plastics, and reinforced plastics. Blended with PVC, PUR, PC, PSU, etc. to make a polymer alloy with excellent performance.

How to improve the heat resistance of ABS plastic?

1. Let the molecular model of the polymer form a three-dimensional structure and form a mesh, thereby inhibiting molecular movement;

2. Add aromatic and alicyclic structures that are difficult to move into the molecular structure;

3. Add polar groups to the polymer, thereby relying on the binding force of the hydrogen-oxygen chain to inhibit the molecular structure;

4. Introduce the crystal structure into the polymer structure for heat-resistant modification, using heat-resistant modifiers.

ABS modified series includes heat-resistant grade, electroplating grade, high-gloss grade, flame-retardant grade, etc., with complete categories and excellent performance, widely used in home appliances, auto parts, building materials, etc.

DOME Materials can provide custom modified ABS keyboard materials (70%-80% transparent new/recycled ABS raw materials + 30%-20% PMMA + 4% Laser Marking Additives)

The black keyboard is marked white, and the laser marking effect is as follows:

One Response